Какова прочность алюминиевых листов при различных нагрузках

Алюминиевые листы являются одним из наиболее универсальных материалов в современной промышленности благодаря своему легкому весу, коррозионной стойкости и выдающимся механическим свойствам. Однако прочность этих материалов не является постоянной величиной; она варьируется в зависимости от типа нагрузки, состава сплава, термической обработки и других факторов. В этой статье мы подробно рассмотрим, как прочность алюминиевых листов изменяется под воздействием различных нагрузок, включая растяжение, сжатие, изгиб, удар и циклические нагрузки. Мы также обсудим ключевые аспекты, такие как влияние сплавов, методов производства, тестирования и практического применения в отраслях, таких как строительство, авиация и автомобилестроение. Цель — предоставить глубокое понимание для инженеров, проектировщиков и специалистов, работающих с этим материалом.

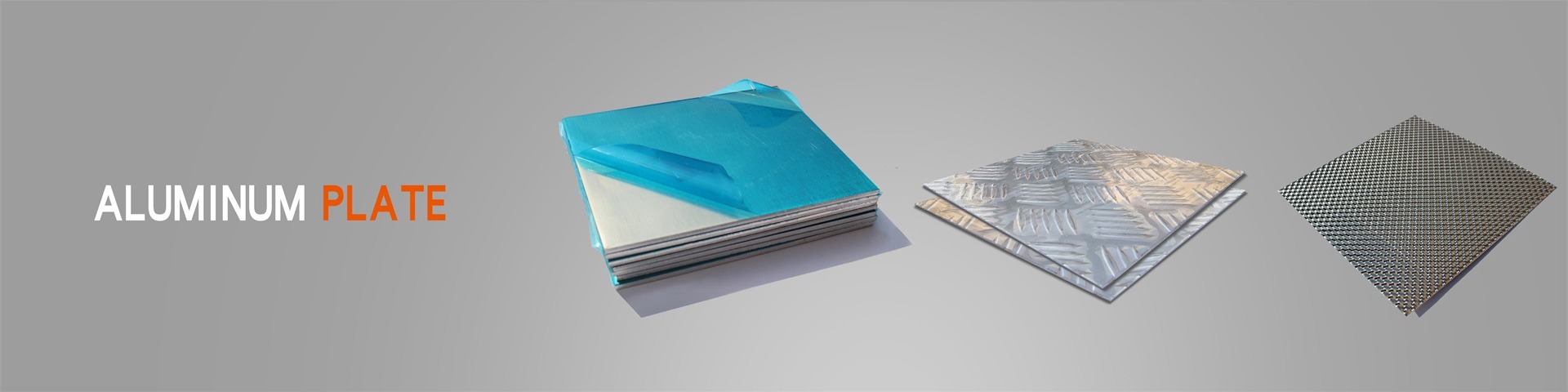

Введение в алюминиевые листы и их свойства

Алюминиевые листы производятся из алюминия и его сплавов, которые обладают уникальным сочетанием свойств: низкой плотностью (около 2,7 г/см³), высокой электропроводностью и теплопроводностью, а также отличной обрабатываемостью. Прочность алюминиевых листов определяется их способностью сопротивляться деформации или разрушению под нагрузкой. Это свойство зависит от микроструктуры материала, которая, в свою очередь, формируется в процессе производства, включая прокатку, литье и термическую обработку. Алюминиевые сплавы, такие как серии 1xxx (чистый алюминий), 2xxx (медно-алюминиевые сплавы), 5xxx (магниево-алюминиевые сплавы), 6xxx (магниево-кремниевые сплавы) и 7xxx (цинково-алюминиевые сплавы), предлагают широкий диапазон прочностных характеристик. Например, сплавы серии 7xxx, такие как 7075, могут достигать прочности на растяжение до 570 МПа, в то время как чистый алюминий (серия 1xxx) имеет прочность всего около 90 МПа. Эти различия делают алюминиевые листы пригодными для разнообразных применений, от упаковки до аэрокосмических компонентов. Понимание прочности под различными нагрузками критически важно для оптимизации дизайна и обеспечения безопасности в конечных продуктах.

Прочность при растягивающих нагрузках

Растягивающие нагрузки являются одним из наиболее распространенных типов напряжений, испытываемых алюминиевыми листами в таких применениях, как конструкционные элементы или обшивка. Прочность на растяжение измеряется как максимальное напряжение, которое материал может выдержать перед разрушением, и обычно выражается в мегапаскалях (МПа) или килограммах на квадратный миллиметр (кг/мм²). Для алюминиевых листов прочность на растяжение зависит от сплава и состояния материала. Например, алюминиевый сплав 6061 в состоянии T6 имеет прочность на растяжение около 310 МПа, в то время как сплав 2024 в состоянии T3 достигает 470 МПа. Кривая напряжение-деформация для алюминиевых листов под растяжением typically показывает упругую область, где деформация обратима, и пластическую область, где происходит необратимая деформация. Предел текучести, точка, при которой материал начинает деформироваться пластически, также является ключевым параметром; для многих алюминиевых сплавов он составляет от 100 до 500 МПа. Факторы, влияющие на прочность при растяжении, включают состав сплава (например, добавление меди или цинка увеличивает прочность), толщину листа (более тонкие листы могут иметь slightly different properties due to grain size effects), и наличие дефектов, таких как porosity or inclusions. Testing is conducted using tensile testing machines according to standards like ASTM E8 or ISO 6892-1, where a specimen is pulled until failure, and data on ultimate tensile strength, yield strength, and elongation are recorded. This information is crucial for design engineers to ensure that components can withstand expected loads without failure.

Прочность при сжимающих нагрузках

Сжимающие нагрузки возникают, когда сила прикладывается к материалу, сжимая его, как в колоннах или опорных конструкциях. Прочность алюминиевых листов при сжатии often differs from tensile strength due to the material's anisotropic behavior and buckling tendencies. For thin sheets, compressive strength is closely related to buckling resistance, which depends on the sheet's geometry, support conditions, and material properties. The compressive yield strength is typically similar to the tensile yield strength for most aluminum alloys, but the ultimate compressive strength can be lower if buckling occurs before material failure. For instance, an aluminum alloy like 5083 might have a compressive yield strength of around 215 MPa, comparable to its tensile yield strength. However, in practical applications, engineers must consider Euler's buckling formula for columns or plate buckling theories to prevent premature failure. Factors such as thickness, aspect ratio, and edge constraints play a significant role; thicker sheets or those with reinforced edges exhibit higher compressive strength. Additionally, the microstructure influences behavior; fine-grained materials may have better resistance to compression. Testing compressive strength involves using compression testers or specialized fixtures in universal testing machines, following standards like ASTM E9. Results help in designing compressed members in aerospace fuselages, automotive frames, or building structures, where weight savings are critical but safety cannot be compromised.

Прочность при изгибающих нагрузках

Изгибающие нагрузки common in beams, panels, and other flexural elements cause a combination of tensile and compressive stresses on opposite sides of the neutral axis. The strength of aluminum sheets under bending is evaluated through parameters like flexural strength, which is the stress at failure in a bending test, and modulus of rupture. Bending behavior depends on the alloy's ductility and hardness; ductile alloys like those in the 5xxx series can undergo significant bending without cracking, while harder alloys like 7xxx may be more prone to fracture. The bend radius is a critical factor; smaller bend radii increase stress and risk of failure. For example, a typical aluminum sheet might have a minimum bend radius of 1-2 times its thickness for alloys like 3003, but this varies with temper and alloy composition. Testing involves three-point or four-point bend tests per standards such as ASTM E290, where a specimen is supported at two points and loaded at the center or multiple points until failure. The results provide insights into formability and durability in applications like automotive body panels, where sheets are often bent into shape. Factors affecting bending strength include grain direction (anisotropy from rolling), surface finish, and any previous cold work, which can alter material properties. Proper design must account for these to avoid issues like springback or cracking during manufacturing.

Прочность при ударных нагрузках

Ударные нагрузки involve sudden, high-force applications, such as in crash scenarios or impact events, where the material's ability to absorb energy without fracturing is crucial. The toughness of aluminum sheets, measured by impact strength, is a key indicator of performance under such conditions. This is often assessed using Charpy or Izod impact tests, which measure the energy absorbed by a notched specimen when struck by a pendulum. Aluminum alloys generally have good impact resistance due to their ductility, but it varies with alloy type and heat treatment. For instance, alloys in the 5xxx series (e.g., 5052) exhibit excellent impact toughness, making them suitable for marine applications or protective structures, whereas high-strength alloys like 7075 may be more brittle and have lower impact strength. The thickness of the sheet also affects impact behavior; thicker sheets can dissipate energy more effectively through plastic deformation. Microstructural features, such as grain size and precipitate distribution, influence crack propagation; finer grains often enhance toughness. In practical terms, this means that aluminum sheets used in automotive bumpers or aerospace skins must be selected based on expected impact scenarios, with simulations and testing validating designs. Standards like ASTM E23 guide impact testing, providing data that help engineers balance strength and toughness for safety-critical applications.

Прочность при циклических нагрузках (усталость)

Циклические нагрузки, or fatigue, occur when a material is subjected to repeated or fluctuating stresses, leading to failure at stresses below the static strength limit. Fatigue strength is a critical property for aluminum sheets in dynamic applications like aircraft wings, bridges, or rotating machinery. It is characterized by the S-N curve (stress vs. number of cycles to failure), where endurance limit may exist for some alloys, but aluminum generally does not have a true endurance limit, meaning failure can occur at any stress level given enough cycles. The fatigue strength of aluminum sheets depends on factors such as alloy composition, surface condition, and mean stress. For example, alloy 2024-T3 has a fatigue strength of about 140 MPa at 10^7 cycles, while alloy 6061-T6 might have around 90 MPa. Surface treatments like shot peening or anodizing can improve fatigue resistance by introducing compressive stresses or reducing crack initiation sites. Testing is done using fatigue testing machines that apply cyclic loads, following standards like ASTM E466. Results are used to predict service life and design for durability, often incorporating safety factors to account for variability in loading conditions. In industries like aerospace, where weight and reliability are paramount, understanding fatigue behavior is essential to prevent catastrophic failures.

Влияние сплавов и термической обработки

Состав сплава и термическая обработка profoundly affect the strength of aluminum sheets under various loads. Aluminum alloys are categorized into series based on major alloying elements: 1xxx (pure Al, low strength, high conductivity), 2xxx (Cu, high strength but lower corrosion resistance), 3xxx (Mn, moderate strength, good formability), 4xxx (Si, used for welding), 5xxx (Mg, excellent corrosion resistance and moderate strength), 6xxx (Mg and Si, good strength and formability), and 7xxx (Zn, very high strength). Heat treatment processes such as solution heat treatment, quenching, and aging (e.g., T6 temper) can significantly enhance strength by forming precipitates that hinder dislocation movement. For instance, 7075 aluminum in T6 condition achieves tensile strengths up to 570 MPa due to Zn and Mg additions and proper aging. Conversely, annealing can soften the material, reducing strength but improving ductility. The choice of alloy and temper depends on the application: 5xxx series might be chosen for marine environments due to corrosion resistance, while 7xxx series is preferred for aerospace where high strength-to-weight ratio is needed. Microstructural analysis, including grain size and precipitate distribution, helps tailor properties for specific load conditions. This customization allows engineers to optimize performance, whether for static loads in buildings or dynamic loads in vehicles.

Методы тестирования и стандарты

Accurate assessment of aluminum sheet strength requires standardized testing methods. Tensile testing (ASTM E8) measures ultimate tensile strength, yield strength, and elongation. Compression testing (ASTM E9) evaluates behavior under squashing loads. Bend testing (ASTM E290) assesses formability and flexural strength. Impact testing (ASTM E23) determines toughness under sudden loads. Fatigue testing (ASTM E466) studies endurance under cyclic stresses. Additionally, non-destructive tests like ultrasonic testing or hardness tests (e.g., Brinell or Rockwell) provide supplementary data. These tests are conducted in controlled laboratories using calibrated equipment, and results are compared to material specifications to ensure quality. International standards from organizations like ISO, EN, and GOST provide guidelines for consistency across industries. For example, GOST 1497-84 covers tensile testing for metals in Russia. Proper testing not only validates material properties but also helps in research and development of new alloys or processes, enabling innovations that enhance performance under diverse loading scenarios.

Применение в различных отраслях

Алюминиевые листы find applications across multiple industries due to their adaptable strength properties. In construction, they are used for roofing, cladding, and structural components, where strength under wind, snow, and dead loads is vital; alloys like 3003 or 5052 offer a balance of strength and corrosion resistance. In aerospace, high-strength alloys such as 2024 or 7075 are employed for fuselage skins and wings, where fatigue and impact resistance are critical for safety. Automotive industry uses aluminum sheets for body panels, bumpers, and chassis parts to reduce weight and improve fuel efficiency, with alloys like 5182 or 6016 providing good formability and strength. Marine applications rely on 5xxx series for hulls and decks due to excellent corrosion resistance and moderate strength. Electronics and packaging use thinner sheets for heat sinks or cans, where strength is less critical but formability is key. Each industry selects alloys and tempers based on specific load requirements, often using finite element analysis (FEA) to simulate behavior and optimize designs. This versatility makes aluminum sheets indispensable in modern engineering.

Заключение и будущие тенденции

В заключение, прочность алюминиевых листов при различных нагрузках is a complex interplay of material composition, processing, and external factors. From tensile to impact loads, each type demands careful consideration in design and selection. Advances in metallurgy, such as development of new alloys or nano-structured materials, promise even higher strength and better performance. For instance, aluminum-lithium alloys offer improved strength-to-weight ratios for aerospace. Additionally, additive manufacturing (3D printing) with aluminum powders is opening new possibilities for customized components with optimized strength profiles. Sustainability trends are driving recycling of aluminum, which retains much of its strength properties, reducing environmental impact. Future research will likely focus on enhancing toughness and fatigue resistance through microengineering and smart coatings. As industries continue to prioritize lightweighting and efficiency, understanding and leveraging the strength of aluminum sheets under diverse loads will remain crucial for innovation and safety. Engineers must stay informed through continuous testing and adoption of best practices to harness the full potential of this remarkable material.