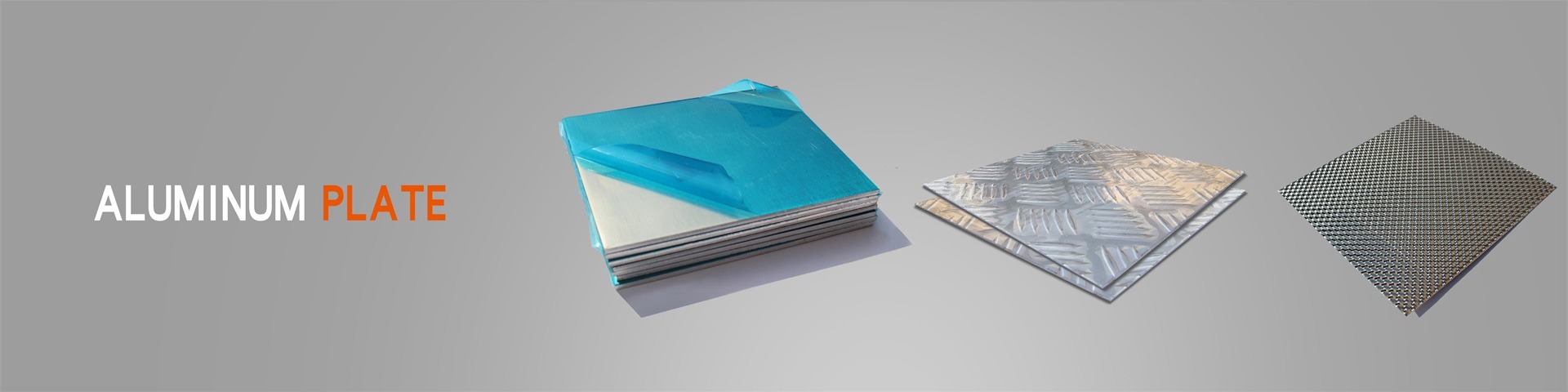

Современные фасады из 3003 алюминиевой ромбовидной плиты

В современной архитектуре фасады играют ключевую роль не только в эстетическом восприятии зданий, но и в их функциональности, энергоэффективности и долговечности. Среди множества материалов, используемых для облицовки, алюминиевые плиты, особенно из сплава 3003 с ромбовидным рисунком, выделяются своими уникальными свойствами. Эта статья предоставляет всесторонний анализ применения 3003 алюминиевой ромбовидной плиты в фасадных системах, рассматривая технические аспекты, преимущества, практические примеры и будущие тенденции. Мы углубимся в детали, чтобы помочь архитекторам, инженерам и застройщикам сделать informed решения для своих проектов.

Введение в алюминиевые фасадные системы

Алюминий, как материал, зарекомендовал себя в строительной индустрии благодаря своей легкости, коррозионной стойкости и универсальности. Фасадные системы на основе алюминия стали популярными в последние десятилетия, предлагая решения для различных климатических условий и архитектурных стилей. Ромбовидная плита из сплава 3003 добавляет эстетическую привлекательность и функциональные преимущества, такие как улучшенная вентиляция и структурная integrity. В этом разделе мы обсудим общие принципы алюминиевых фасадов и почему 3003 сплав является предпочтительным выбором.

Алюминиевые фасады часто используются в вентилируемых системах, которые позволяют воздуху циркулировать за облицовкой, reducing moisture buildup and improving thermal performance. The use of patterned sheets, like the rhombic design, not only enhances visual appeal but also can contribute to light diffusion and shadow play, adding depth to building exteriors. Alloy 3003, a manganese-based alloy, is known for its excellent formability and resistance to corrosion, making it ideal for outdoor applications where durability is paramount.

Характеристики сплава 3003 алюминия

Сплав 3003 относится к серии алюминиево-марганцевых сплавов, которые широко применяются в строительстве due to their balanced properties. It consists primarily of aluminum with about 1.2% manganese, which enhances strength without significantly compromising ductility. Key characteristics include:

- Высокая коррозионная стойкость, особенно в атмосферных условиях, что делает его suitable for facades exposed to rain, snow, and pollutants.

- Хорошая свариваемость и обрабатываемость, allowing for easy fabrication into various shapes, including the intricate rhombic pattern.

- Умеренная прочность, with a tensile strength of around 110 MPa, which is sufficient for most facade applications without adding excessive weight.

- Легкость, with a density of approximately 2.7 g/cm³, reducing the load on the building structure and facilitating installation.

These properties make alloy 3003 a cost-effective choice for facade cladding, as it combines performance with affordability. Compared to other alloys like 5005 or 6061, 3003 offers better formability, which is crucial for creating the repetitive rhombic pattern without cracking or deformation during manufacturing.

Преимущества ромбовидной плиты в фасадах

Ромбовидный рисунок на алюминиевой плите не только служит декоративным элементом, но и предоставляет функциональные выгоды. Основные преимущества включают:

- Эстетическая универсальность: Ромбовидный pattern adds a modern, geometric look that can be adapted to various architectural styles, from minimalist to avant-garde. It creates visual interest through light and shadow effects, changing appearance throughout the day.

- Улучшенная вентиляция: The open design of the rhombic pattern allows for better air flow in ventilated facade systems, helping to regulate temperature and reduce condensation, which can prevent mold growth and structural damage.

- Повышенная жесткость: The patterned surface can increase the stiffness of the sheet, reducing the risk of denting or warping under wind loads or impact, thus enhancing durability.

- Легкость очистки and maintenance: The raised pattern can make it easier to clean, as dirt and debris are less likely to accumulate in flat areas, and rainwater can wash away contaminants more effectively.

These benefits make rhombic aluminum sheets a practical choice for both new constructions and renovations, where aesthetics and performance are equally important.

Процесс производства и обработки

Изготовление 3003 алюминиевой ромбовидной плиты involves several steps to ensure quality and consistency. The process typically includes:

- Литье и прокатка: The aluminum alloy is cast into ingots, which are then hot and cold rolled to achieve the desired thickness, usually between 1.5mm to 3mm for facade applications.

- Штамповка или перфорация: Using specialized dies or CNC machines, the rhombic pattern is stamped or perforated into the sheet. This requires precise control to maintain pattern uniformity and avoid material weaknesses.

- Отделка поверхности: The sheets may undergo processes like anodizing or powder coating to enhance corrosion resistance and provide color options. Anodizing creates a protective oxide layer, while powder coating offers a wide range of colors and finishes.

- Контроль качества: Each sheet is inspected for defects, dimensional accuracy, and coating adhesion to meet industry standards such as EN 1396 for aluminum sheets used in construction.

Advanced manufacturing techniques, such as laser cutting, allow for complex patterns with high precision, reducing waste and improving efficiency. The use of alloy 3003 ensures that the sheets remain formable during these processes, minimizing the risk of cracking.

Применение в современных зданиях

3003 алюминиевая ромбовидная плита находит применение в разнообразных проектах, от коммерческих небоскребов до жилых комплексов. Примеры включают:

- Офисные здания: Facades with rhombic patterns can create a dynamic exterior that reflects corporate identity while providing functional benefits like solar shading and energy efficiency. For instance, the use in high-rise buildings in urban areas helps reduce heat gain through improved ventilation.

- Культурные и общественные сооружения: Museums, theaters, and schools often use such facades to achieve a modern look that stands out. The pattern can be customized in size and orientation to match architectural themes.

- Жилые проекты: In residential buildings, these sheets offer a sleek alternative to traditional materials, enhancing curb appeal and property value. They are particularly popular in contemporary home designs where light and privacy are balanced through the patterned cladding.

- Реконструкция: Existing buildings can be upgraded with rhombic aluminum facades to improve appearance and performance without major structural changes, thanks to the light weight of the material.

Case studies show that projects using 3003 aluminum rhombic sheets often report reduced maintenance costs and longer service life compared to other cladding options like glass or steel.

Монтаж и техническое обслуживание

Установка фасадных систем из ромбовидной плиты требует careful planning and expertise. Key steps in the installation process include:

- Подготовка substrate: The building's exterior must be properly prepared, with a framework (often aluminum or steel) installed to support the cladding. This framework ensures even distribution of loads and allows for thermal expansion.

- Крепление плит: The rhombic sheets are attached using mechanical fasteners or clips designed to accommodate movement due to temperature changes. It's essential to follow manufacturer guidelines to avoid issues like leakage or detachment.

- Герметизация и изоляция: Joints between sheets are sealed to prevent water ingress, and insulation layers may be added behind the cladding to enhance thermal performance.

- Регулярное обслуживание: While low-maintenance, periodic cleaning with mild detergents and inspections for damage are recommended to prolong lifespan. The durability of alloy 3003 means that repairs are rarely needed, but touch-ups to coatings might be necessary over time.

Proper installation by certified professionals ensures that the facade performs as intended, meeting safety standards and building codes.

Экологические аспекты и устойчивость

Использование алюминия в строительстве aligns with green building practices due to its recyclability and energy efficiency. Alloy 3003, in particular, offers environmental benefits:

- Высокая степень переработки: Aluminum is 100% recyclable without loss of quality, and using recycled content in production reduces energy consumption by up to 95% compared to primary aluminum.

- Энергоэффективность: Ventilated facades with rhombic sheets can improve a building's thermal performance, reducing heating and cooling costs. This contributes to lower carbon emissions over the building's lifecycle.

- Долговечность: Long service life means less frequent replacements, minimizing waste. The corrosion resistance of 3003 alloy ensures that the material remains functional for decades, even in harsh environments.

- Сертификации: Many projects aim for certifications like LEED or BREEAM, where the use of sustainable materials like aluminum can earn points towards higher ratings.

By choosing 3003 aluminum rhombic sheets, developers can support sustainable construction while achieving aesthetic goals.

Сравнение с другими материалами

Чтобы оценить эффективность 3003 алюминиевой ромбовидной плиты, полезно сравнить ее с альтернативами, такими как сталь, стекло или композитные материалы.

- По сравнению со сталью: Алюминий легче и более устойчив к коррозии, что снижает затраты на техническое обслуживание. Однако сталь может предложить higher strength, but it often requires protective coatings and is prone to rust.

- По сравнению со стеклом: Стеклянные фасады обеспечивают прозрачность и modern look, but they are heavier, more fragile, and less energy-efficient without additional treatments. Алюминиевые плиты offer better durability and customization.

- По сравнению с композитными материалами: Композитные панели могут быть легкими и colorful, but they may delaminate over time and have lower fire resistance. Алюминий provides a more robust and fire-safe option, though it might be slightly more expensive initially.

Overall, 3003 aluminum rhombic sheets strike a balance between cost, performance, and aesthetics, making them a versatile choice for many applications.

Будущие тенденции и инновации

Будущее фасадных технологий видится в интеграции smart features and advanced materials. For 3003 aluminum rhombic sheets, trends include:

- Интеллектуальные фасады: Integration with sensors and IoT devices to monitor environmental conditions and adjust ventilation automatically, enhancing energy efficiency.

- Улучшенные покрытия: Development of self-cleaning or photocatalytic coatings that break down pollutants, keeping facades cleaner and reducing maintenance.

- Кастомизация: Advances in digital manufacturing allow for bespoke patterns and sizes, enabling architects to create unique designs without compromising on performance.

- Устойчивость: Increased use of recycled aluminum and bio-based coatings to further reduce environmental impact.

These innovations will likely make rhombic aluminum facades even more attractive in the coming years, driving adoption in cutting-edge architectural projects.

Заключение

3003 алюминиевая ромбовидная плита представляет собой выдающееся решение для современных фасадов, combining aesthetic appeal with practical benefits. Its corrosion resistance, formability, and environmental sustainability make it a preferred choice for architects and builders worldwide. As technology advances, we can expect to see even more creative and efficient uses of this material, solidifying its place in the future of construction. By embracing such innovations, the industry can create buildings that are not only beautiful but also resilient and eco-friendly.

Для успешной реализации проектов рекомендуется сотрудничать с experienced suppliers and installers who can provide guidance on best practices and ensure that the facade systems meet all regulatory requirements. With proper planning and execution, 3003 aluminum rhombic sheets can transform any building into a landmark of modern design.