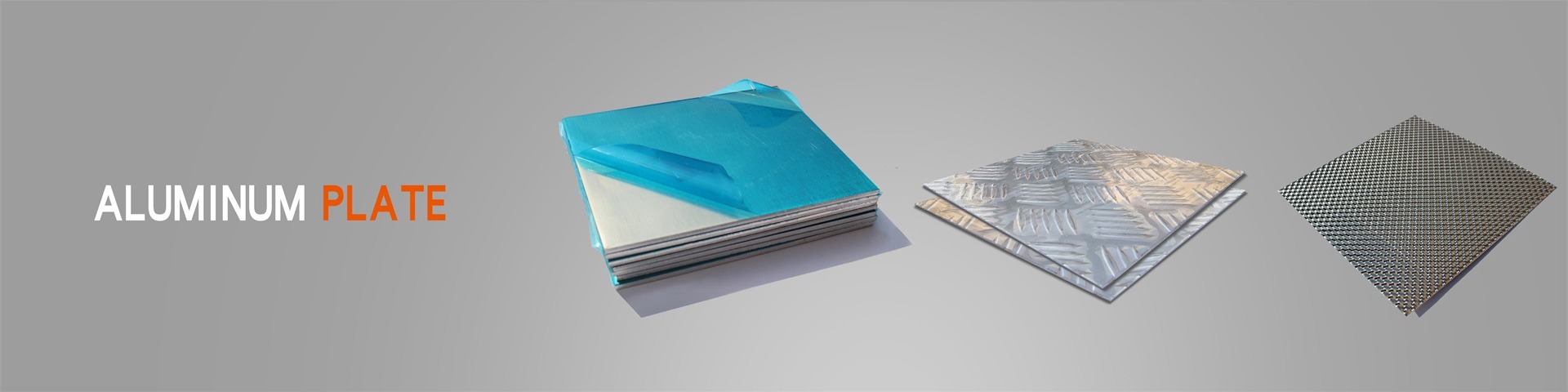

Совершенная полировка алюминиевых листов для идеального блеска и прочности

Алюминий, как один из самых распространенных металлов в современной промышленности, обладает уникальными свойствами: легкостью, коррозионной стойкостью и отличной обрабатываемостью. Однако для достижения идеального блеска и максимальной прочности алюминиевых листов требуется тщательная полировка. В этой статье мы рассмотрим ключевые аспекты совершенной полировки, включая выбор материалов, технологические процессы, преимущества и практические применения. Мы углубимся в детали, чтобы предоставить всестороннее руководство для профессионалов и энтузиастов.

Введение в полировку алюминиевых листов

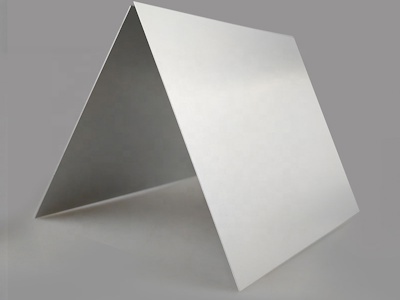

Полировка алюминиевых листов — это не просто эстетическая процедура; она играет crucial роль в улучшении механических свойств материала. Алюминий, будучи мягким металлом, легко подвергается царапинам и деформациям, но правильная полировка может значительно усилить его поверхностную твердость и устойчивость к износу. Процесс включает удаление микронеровностей, окисных пленок и других дефектов с поверхности, что приводит к гладкому, зеркальному блеску. Это особенно важно в отраслях, где внешний вид и долговечность имеют первостепенное значение, таких как аэрокосмическая, автомобильная и строительная промышленности.

Исторически, полировка металлов восходит к древним временам, когда мастера использовали простые абразивы для придания блеска украшениям и оружию. С развитием технологий, методы полировки эволюционировали, и сегодня мы имеем доступ к advanced equipment and chemicals that ensure precision and efficiency. Для алюминиевых листов, которые часто используются в large-scale applications, such as cladding for buildings or components in machinery, achieving a perfect polish is essential not only for aesthetics but also for functional reasons, like reducing friction and improving corrosion resistance.

В этом разделе мы установили базовое понимание важности полировки. Далее, мы подробно обсудим материалы и оборудование, необходимые для этого процесса.

Материалы и оборудование для полировки

Выбор правильных материалов и оборудования является фундаментальным для успешной полировки алюминиевых листов. Алюминиевые листы typically come in various alloys, such as 1000 series (pure aluminum) or 6000 series (with magnesium and silicon), each with different properties that affect the polishing process. For instance, pure aluminum is softer and easier to polish but may require more care to avoid over-polishing, while alloyed aluminum offers better strength but might need specialized abrasives.

Key equipment includes polishing machines, which can range from handheld tools for small projects to automated systems for industrial-scale production. Common types include belt sanders, orbital polishers, and buffing wheels. Abrasives are equally important; they come in various grits, from coarse (e.g., 80 grit for initial roughing) to fine (e.g., 2000 grit for final polishing). Additionally, polishing compounds, such as those based on aluminum oxide or diamond paste, are used to enhance the finish. For aluminum, it's crucial to use non-ferrous abrasives to prevent contamination and galvanic corrosion.

Chemical polishes are another option, involving acids or alkaline solutions that etch the surface to achieve a smooth finish. However, these require careful handling due to safety concerns. Protective gear, such as gloves and goggles, is essential to avoid injuries. In industrial settings, automated polishing lines integrate these elements with conveyors and robotics to ensure consistency and high throughput.

Investing in quality materials and equipment not only improves the results but also reduces the time and effort required. For example, a high-quality buffing wheel can last longer and provide a more uniform finish compared to cheaper alternatives. Moreover, using the right abrasive sequence—starting with coarse grits and gradually moving to finer ones—helps in achieving that perfect mirror-like shine without leaving scratches.

This section highlights the importance of preparation. Next, we will delve into the step-by-step polishing process.

Пошаговый процесс полировки

The polishing process for aluminum sheets can be broken down into several stages: cleaning, rough polishing, fine polishing, and finishing. Each stage requires attention to detail to ensure optimal results.

First, cleaning the aluminum sheet is crucial to remove any dirt, oils, or oxides that might interfere with polishing. This can be done using solvents like acetone or isopropyl alcohol, followed by a rinse with water. For industrial applications, ultrasonic cleaners are often employed for thorough cleaning.

Next, rough polishing involves using coarse abrasives (e.g., 120-220 grit) to remove major imperfections, such as scratches or mill scale. This stage flatten the surface and prepares it for finer abrasives. It's important to work in a consistent direction to avoid creating new scratches. Automated machines can help maintain uniformity, especially for large sheets.

Fine polishing uses medium to fine abrasives (e.g., 400-1000 grit) to further smooth the surface. Here, the goal is to eliminate the marks left by rough polishing and achieve a semi-gloss finish. Polishing compounds are applied at this stage to enhance the cutting action and lubricate the surface, reducing heat buildup that could warp the aluminum.

The final stage, finishing, employs very fine abrasives (e.g., 1500-2000 grit) or polishing pastes to produce a high-gloss, mirror-like finish. Buffing wheels with soft materials like felt or cloth are used to apply the final polish. After polishing, a thorough cleaning is necessary to remove any residue, followed by optional protective coatings, such as clear lacquer or anodizing, to preserve the shine and prevent oxidation.

Throughout the process, it's vital to control factors like pressure, speed, and temperature. Excessive pressure can cause overheating and deformation, while too little may not achieve the desired finish. Using coolants or lubricants can help manage heat. For DIY enthusiasts, practicing on scrap pieces is recommended to gain experience.

This detailed process ensures that the aluminum sheet not only looks impeccable but also gains enhanced durability. In the next section, we explore the benefits of such polishing.

Преимущества полировки алюминиевых листов

Polishing aluminum sheets offers numerous advantages beyond mere aesthetics. Firstly, it significantly improves the surface hardness and wear resistance. By removing micro-imperfections, the polished surface becomes less prone to scratches and abrasions, which is critical in applications like automotive parts or architectural elements exposed to harsh environments.

Secondly, a polished surface enhances corrosion resistance. Aluminum naturally forms a protective oxide layer, but polishing can make this layer more uniform and adherent, reducing the risk of pitting and corrosion. This is especially beneficial in marine or industrial settings where moisture and chemicals are present.

Thirdly, polishing improves functional properties. For instance, in heat exchangers or electronic enclosures, a smooth surface reduces friction and improves heat dissipation. In decorative applications, the mirror-like finish adds value and appeal, making products more attractive to consumers.

Economically, polished aluminum sheets can lead to cost savings in the long run. They require less maintenance and have a longer lifespan, reducing replacement costs. Additionally, the process can be automated for mass production, ensuring consistency and efficiency.

From an environmental perspective, polishing can be done with eco-friendly abrasives and chemicals, minimizing waste and pollution. Proper disposal of used materials is part of responsible practices.

These benefits make polishing a worthwhile investment for various industries. In the following section, we discuss practical applications and case studies.

Практические применения и примеры из практики

Polished aluminum sheets find applications across multiple sectors. In the automotive industry, they are used for trim, grilles, and interior components where shine and durability are key. For example, luxury car manufacturers often use highly polished aluminum to enhance the vehicle's appearance and resist road debris.

In construction, polished aluminum is popular for cladding, signage, and decorative panels. Buildings with aluminum facades benefit from the material's lightweight nature and reflective properties, which can improve energy efficiency by reflecting sunlight. A case study from a skyscraper project showed that using polished aluminum reduced cooling costs by 15% due to its high reflectivity.

The aerospace industry relies on polished aluminum for aircraft skins and components to reduce drag and improve fuel efficiency. Strict standards ensure that the polishing process meets safety and performance requirements. For instance, Boeing incorporates advanced polishing techniques to achieve surfaces that minimize air resistance.

In consumer goods, items like smartphones, laptops, and appliances use polished aluminum for a sleek, modern look. Apple's products are a prime example, where the aluminum casings are meticulously polished to achieve a premium finish.

These real-world examples demonstrate the versatility and importance of perfect polishing. Challenges such as achieving consistency in large batches or dealing with complex shapes are addressed through innovative technologies like robotic polishing arms.

This section underscores the practical relevance. Next, we will look at common challenges and solutions in the polishing process.

Вызовы и решения при полировке

Despite its benefits, polishing aluminum sheets comes with challenges. One common issue is orange peel effect, where the surface appears wavy due to uneven polishing. This can be mitigated by using finer abrasives and maintaining consistent pressure.

Another challenge is heat generation, which can cause the aluminum to warp or discolor. Solutions include using coolants, reducing polishing speed, and employing intermittent polishing to allow cooling. Automated systems often have built-in temperature controls.

Contamination from ferrous materials can lead to galvanic corrosion. Using non-ferrous abrasives and keeping the work area clean helps prevent this. Regular inspection of equipment for wear and tear is also important.

For large sheets, handling and uniformity can be problematic. Robotics and conveyor systems ensure even polishing across the entire surface. In DIY settings, using jigs or fixtures can help maintain alignment.

Cost can be a barrier, especially for small businesses. However, investing in quality equipment pays off through reduced labor and better results. Leasing or sharing resources in industrial parks is a viable option for some.

By addressing these challenges proactively, manufacturers can achieve consistent, high-quality polishes. The next section discusses future trends and innovations in aluminum polishing.

Будущие тенденции и инновации

The field of aluminum polishing is evolving with advancements in technology. One trend is the use of laser polishing, which offers precise control without physical contact, reducing the risk of damage and allowing for complex geometries. This method is gaining traction in high-precision industries like medical devices.

Another innovation is the development of eco-friendly polishing compounds that are biodegradable and non-toxic. As sustainability becomes a priority, these products help reduce environmental impact.

Automation and AI are revolutionizing polishing processes. Smart systems can adapt in real-time to variations in the material, ensuring consistent results. For example, AI-powered vision systems detect defects and adjust polishing parameters accordingly.

Nanotechnology is also making inroads, with nano-abrasives that provide smoother finishes at the microscopic level. This could lead to even higher levels of gloss and durability.

These innovations promise to make polishing more efficient, accessible, and sustainable. Keeping abreast of these trends can give businesses a competitive edge.

Заключение

In conclusion, perfect polishing of aluminum sheets is essential for achieving ideal shine and strength. Through careful selection of materials, adherence to a detailed process, and overcoming challenges, manufacturers can unlock the full potential of aluminum. The benefits span aesthetics, functionality, and economics, making it a valuable practice across industries. As technology advances, the future holds even greater possibilities for innovation in this field. By embracing these developments, we can continue to enhance the quality and applications of polished aluminum.