Какие свойства делают алюминиевый рулон идеальным для строительства

В современном строительстве выбор материалов играет ключевую роль в обеспечении долговечности, экономичности и экологичности проектов. Одним из таких материалов является алюминиевый рулон, который находит широкое применение благодаря своим уникальным свойствам. Но что именно делает алюминиевый рулон таким идеальным для строительных нужд? В этой статье мы глубоко погрузимся в этот вопрос, рассмотрев все аспекты от физических характеристик до практического использования, чтобы помочь вам понять, почему алюминий часто становится материалом выбора для архитекторов, инженеров и строителей.

Введение в алюминиевый рулон

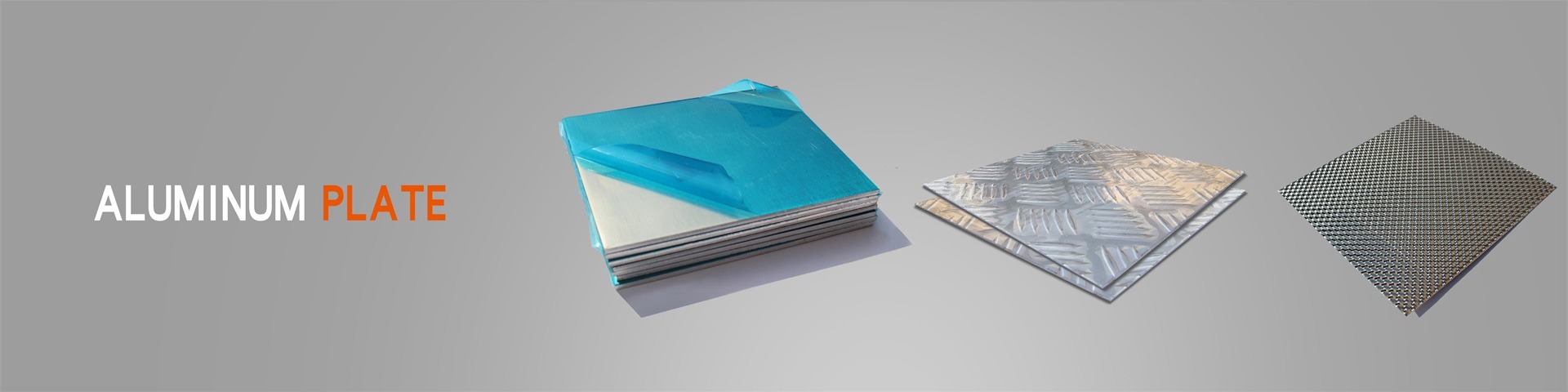

Алюминиевый рулон – это листовой материал, произведенный из алюминия и его сплавов, свернутый в удобную для транспортировки и обработки форму. Его использование в строительстве началось еще в середине XX века и с тех пор только расширялось. Алюминий, как металл, обладает рядом врожденных качеств, которые делают его привлекательным для различных отраслей, но именно в строительстве эти свойства раскрываются в полной мере. Легкость, прочность, коррозионная стойкость – это лишь некоторые из них. Однако, чтобы полностью оценить преимущества алюминиевого рулона, необходимо детально изучить каждое свойство и то, как оно влияет на строительные процессы.

Строительная индустрия постоянно ищет материалы, которые могут снизить общий вес конструкций без ущерба для прочности, и алюминий идеально подходит для этой роли. Кроме того, с ростом внимания к устойчивому развитию, экологические аспекты материалов становятся все более важными. Алюминий является одним из наиболее перерабатываемых материалов в мире, что добавляет ему очков в глазах экологов и застройщиков. Но давайте не будем забегать вперед и начнем с основ – что такое алюминиевый рулон и как он производится?

Производство алюминиевого рулона involves several steps, including melting aluminum ingots, rolling them into thin sheets, and then coiling them for distribution. This process allows for precise control over thickness and properties, making it versatile for different applications. From roofing and cladding to insulation and decorative elements, aluminum rolls are used in myriad ways. But it's the intrinsic properties of aluminum that truly set it apart. In the following sections, we'll explore these properties in depth, answering the central question: why is aluminum roll ideal for construction?

Легкость алюминиевого рулона

Одним из самых выдающихся свойств алюминия является его легкость. По сравнению с другими металлами, такими как сталь, алюминий имеет плотность около 2.7 г/см³, что примерно в три раза меньше, чем у стали. Это делает алюминиевый рулон чрезвычайно легким материалом, что имеет несколько важных преимуществ в строительстве.

Во-первых, легкость алюминия позволяет снизить общий вес строительных конструкций. Это особенно важно в высотном строительстве, где каждый килограмм имеет значение для устойчивости и стоимости фундамента. Например, при использовании алюминиевых рулонов для фасадных систем, вес здания может быть significantly reduced, leading to savings on structural supports and foundation work. Кроме того, легкость упрощает транспортировку и монтаж. Рулоны можно легко перевозить на стандартных грузовиках, а монтаж часто требует меньшего количества рабочей силы и оборудования, что снижает затраты и ускоряет сроки проекта.

Но легкость не означает слабость. Алюминий can be alloyed with other elements to enhance its strength, making it suitable for load-bearing applications. For instance, aluminum alloys like 6061 or 3003 are commonly used in construction for their excellent strength-to-weight ratio. This means that structures can be both light and durable, a combination that is hard to achieve with many other materials. In seismic regions, lightweight materials like aluminum are preferred because they reduce the inertial forces during earthquakes, enhancing safety.

Кроме того, легкость алюминиевого рулона делает его идеальным для реконструкции старых зданий, где добавление heavy materials might compromise the existing structure. By using aluminum, architects can modernize buildings without overburdening them. This property also facilitates prefabrication, where components are manufactured off-site and assembled quickly on-site, reducing construction time and disruption.

Однако, важно отметить, что легкость can sometimes be a drawback in applications requiring high mass for stability, such as in some types of flooring. But for most construction purposes, the benefits far outweigh the limitations. Innovations in design and engineering continue to expand the uses of lightweight aluminum, making it a cornerstone of modern construction.

Прочность и долговечность

Прочность – это еще одно ключевое свойство, которое делает алюминиевый рулон идеальным для строительства. Несмотря на свою легкость, алюминий обладает impressive strength, especially when alloyed. Алюминиевые сплавы can have tensile strengths comparable to some steels, but with the added benefit of being lighter.

Долговечность алюминия обусловлена его способностью формировать protective oxide layer when exposed to air. This layer is thin, adherent, and self-healing, meaning that if scratched, it quickly reforms, protecting the metal from further corrosion. This makes aluminum highly resistant to rust and other forms of degradation, which is crucial for construction materials exposed to the elements. For example, in roofing applications, aluminum rolls can last for decades without significant maintenance, whereas other metals might require frequent painting or replacement.

In addition to corrosion resistance, aluminum has good fatigue strength, meaning it can withstand repeated loading and unloading without failing. This is important for structures like bridges or buildings that experience dynamic loads from wind, traffic, or occupancy. Aluminum's durability also makes it suitable for harsh environments, such as coastal areas where salt spray can accelerate corrosion in other metals.

Moreover, aluminum does not become brittle at low temperatures, unlike some materials, which is advantageous in cold climates. It also has good formability, allowing it to be shaped into complex designs without losing strength. This versatility enables architects to create innovative and aesthetically pleasing structures while ensuring structural integrity.

To enhance durability further, aluminum rolls can be coated or anodized. Anodizing increases the thickness of the oxide layer, providing even better corrosion resistance and allowing for color customization. Powder coating is another common treatment that adds a durable, decorative finish. These processes extend the life of aluminum products and reduce long-term maintenance costs.

Examples of aluminum's durability in construction abound. The Empire State Building in New York, though primarily steel, incorporated aluminum in its spire and recent renovations. Modern skyscrapers often use aluminum for curtain walls and windows due to its strength and light weight. In residential construction, aluminum rolls are used for siding, gutters, and downspouts, where durability against weather is paramount.

Коррозионная стойкость

Коррозионная стойкость – это, пожалуй, одно из самых ценных свойств алюминия для строительства. Как упоминалось ранее, алюминий naturally forms a protective oxide layer that prevents rust. This inherent resistance to corrosion means that aluminum rolls require minimal maintenance over their lifespan, reducing overall costs for building owners.

In comparison to materials like steel, which often need galvanizing or painting to prevent rust, aluminum is inherently corrosion-resistant. This is particularly beneficial in environments with high humidity, pollution, or exposure to chemicals. For instance, in industrial buildings or near the ocean, aluminum can outperform other metals without additional treatments.

Aluminum's corrosion resistance also makes it ideal for applications where hygiene is important, such as in food processing plants or hospitals, because it does not harbor bacteria or degrade easily. Additionally, it is non-toxic and does not leach harmful substances, making it safe for use in potable water systems or other sensitive applications.

The ability to resist corrosion extends the service life of structures. Buildings clad with aluminum can maintain their appearance and functionality for 50 years or more with proper care. This longevity contributes to sustainability by reducing the need for replacements and repairs.

However, it's important to note that aluminum can corrode under certain conditions, such as when in contact with dissimilar metals (galvanic corrosion) or in highly acidic or alkaline environments. Proper design and installation can mitigate these risks. For example, using insulation between aluminum and other metals or selecting appropriate alloys can prevent issues.

Overall, the corrosion resistance of aluminum rolls is a major factor in their popularity for construction. It ensures that investments in building materials pay off over the long term through reduced maintenance and enhanced durability.

Теплопроводность и энергоэффективность

Теплопроводность алюминия – это свойство, которое имеет как преимущества, так и challenges в строительстве. Алюминий является excellent conductor of heat, which means it can transfer heat quickly. This can be beneficial in some applications but problematic in others.

On the positive side, high thermal conductivity makes aluminum ideal for heat exchangers, radiators, and other systems where efficient heat transfer is desired. In construction, aluminum rolls are often used in combination with insulation materials to create energy-efficient building envelopes. For example, in curtain walls or roofing systems, aluminum frames can be designed with thermal breaks—materials that reduce heat flow—to minimize energy loss.

Thermal breaks are crucial because without them, aluminum could act as a bridge for heat, leading to higher heating and cooling costs. Modern aluminum systems incorporate polyamide or other insulating materials to disrupt thermal pathways, making them suitable for passive house designs and other high-efficiency standards.

Additionally, aluminum's reflectivity contributes to energy efficiency. Light-colored aluminum surfaces can reflect solar radiation, reducing heat gain in buildings. This is particularly useful in hot climates, where it can lower air conditioning demands. For instance, aluminum roofing rolls with reflective coatings are popular in commercial buildings to achieve energy savings.

On the flip side, in cold climates, the high thermal conductivity might lead to heat loss if not properly addressed. However, with advances in insulation technology, this is easily managed. The overall energy efficiency of a building using aluminum depends on the design and integration with other materials.

Moreover, aluminum is often used in renewable energy systems, such as solar panel frames, due to its light weight and durability. This aligns with the growing trend towards green building practices.

In summary, while thermal conductivity requires careful consideration, it can be turned into an advantage with proper engineering. Aluminum rolls, when used thoughtfully, contribute to energy-efficient and sustainable construction.

Экологичность и переработка

В эпоху growing environmental awareness, the sustainability of building materials is a critical factor. Алюминий excels in this area due to its high recyclability and low environmental impact over its lifecycle.

Алюминий is one of the most recycled materials on Earth. It can be recycled repeatedly without losing its properties, and the recycling process requires only about 5% of the energy needed to produce primary aluminum from bauxite ore. This makes recycled aluminum highly energy-efficient and reduces greenhouse gas emissions.

In construction, using aluminum rolls from recycled content can contribute to LEED (Leadership in Energy and Environmental Design) certification and other green building ratings. Many manufacturers offer aluminum products with high recycled content, appealing to environmentally conscious clients.

Additionally, the longevity of aluminum means that buildings last longer, reducing the frequency of renovations and the associated waste. At the end of its life, aluminum can be easily collected and recycled, closing the loop in a circular economy.

The production of primary aluminum does have environmental impacts, such as energy consumption and emissions, but these are offset by the benefits of recycling. Initiatives to use renewable energy in aluminum production are further reducing its carbon footprint.

Examples of sustainable use include aluminum in modular construction, where components are designed for disassembly and reuse. This approach minimizes waste and resource consumption.

Overall, the eco-friendliness of aluminum rolls makes them an ideal choice for modern construction projects that aim to reduce environmental impact while maintaining performance.

Универсальность в применении

Универсальность алюминиевого рулона is another property that makes it ideal for construction. It can be used in a wide range of applications, from structural elements to decorative features.

In roofing, aluminum rolls provide a lightweight, durable, and weather-resistant covering. They are easy to install and can be formed into various profiles to suit different architectural styles.

For cladding, aluminum offers a modern aesthetic with options for colors and finishes through anodizing or painting. It can mimic other materials like wood or stone while providing better durability.

In insulation, aluminum foil is often used as a vapor barrier or reflective layer in building envelopes to enhance energy efficiency.

Other applications include gutters, downspouts, window frames, and even structural components in some cases. The formability of aluminum allows for custom designs, enabling architects to push the boundaries of creativity.

This versatility means that a single material can meet multiple needs on a construction site, simplifying logistics and reducing costs. It also allows for innovation, as new uses for aluminum are continually being developed.

Экономическая эффективность

Despite initial costs sometimes being higher than other materials, aluminum rolls offer economic benefits in the long run due to their durability, low maintenance, and energy savings.

The light weight reduces transportation and installation costs. Long service life means fewer replacements, and recyclability can provide value at end-of-life.

Energy-efficient designs incorporating aluminum can lead to lower utility bills, adding to the economic advantage.

Overall, the total cost of ownership for aluminum is often lower than for alternatives, making it a smart investment for construction projects.

Заключение

В заключение, алюминиевый рулон обладает множеством свойств, которые делают его идеальным для строительства: легкость, прочность, коррозионная стойкость, теплопроводность (управляемая с помощью термических разрывов), экологичность, универсальность и экономическая эффективность. Эти качества позволяют использовать его в различных applications, от кровли до фасадов, способствуя созданию durable, efficient, and sustainable buildings. As technology advances, the role of aluminum in construction is likely to grow, solidifying its status as a material of choice for the future.

Whether you're an architect, engineer, or builder, considering aluminum rolls for your next project could lead to significant benefits. Embrace the properties that make aluminum ideal, and you'll be investing in a material that stands the test of time.