Алюминиевые листы легко ли поддаются механической обработке

В современном мире промышленности и производства алюминиевые листы занимают особое место благодаря своим уникальным свойствам. Они широко применяются в различных отраслях, от аэрокосмической до строительной, и их механическая обработка часто вызывает вопросы: насколько легко они поддаются таким процессам, как резка, гибка, фрезерование или сварка? В этой статье мы подробно рассмотрим этот вопрос, опираясь на факты, примеры и практический опыт, чтобы помочь вам лучше понять преимущества и нюансы работы с алюминием.

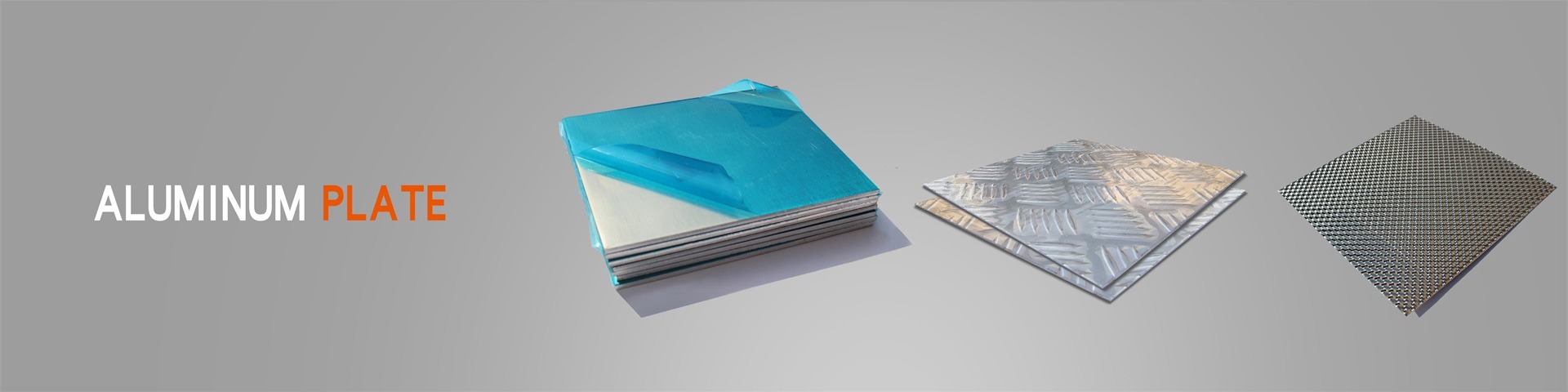

Введение в алюминиевые листы

Алюминий — это лёгкий, прочный и коррозионно-стойкий металл, который добывается из бокситовой руды и проходит процесс электролиза для получения чистого материала. Алюминиевые листы изготавливаются путём прокатки алюминиевых слитков до определённой толщины, которая может варьироваться от нескольких микрометров до нескольких сантиметров. Эти листы обладают высокой пластичностью, что делает их идеальными для механической обработки. Но прежде чем углубиться в детали, давайте определим, что такое механическая обработка. Она включает в себя различные процессы, такие как резка, гибка, сверление, фрезерование, шлифование и сварка, которые используются для придания материалу желаемой формы или размера.

Алюминиевые листы особенно популярны из-за их соотношения прочности и веса. Они весят примерно в три раза меньше, чем стальные листы аналогичного размера, что делает их привлекательными для применений, где вес имеет критическое значение, например, в автомобильной или авиационной промышленности. Кроме того, алюминий обладает естественной оксидной плёнкой, которая защищает его от коррозии, что продлевает срок службы изделий без необходимости дополнительной обработки.

Однако, лёгкость механической обработки зависит от многих факторов, включая тип алюминиевого сплава, толщину листа, используемое оборудование и навыки оператора. В этой статье мы разберём каждый аспект, начиная с общих преимуществ алюминия, затем перейдём к конкретным методам обработки и закончим практическими рекомендациями. Цель — предоставить исчерпывающее руководство, которое поможет как новичкам, так и профессионалам в работе с этим материалом.

Преимущества алюминиевых листов

Прежде чем обсуждать механическую обработку, важно понять, почему алюминиевые листы так востребованы. Их ключевые преимущества включают лёгкость, коррозионную стойкость, высокую теплопроводность, электропроводность и эстетическую привлекательность. Лёгкость — одно из главных достоинств; алюминий имеет плотность около 2,7 г/см³, что значительно меньше, чем у стали (7,8 г/см³). Это позволяет снизить общий вес конструкций, что экономит энергию при транспортировке и эксплуатации, например, в автомобилях или самолётах.

Коррозионная стойкость алюминия обусловлена образованием тонкого слоя оксида алюминия на поверхности, который предотвращает дальнейшее окисление. Это делает его идеальным для использования в агрессивных средах, таких как морские условия или промышленные зоны, где другие металлы могут быстро ржаветь. Кроме того, алюминий легко поддаётся анодированию или покраске, что enhances его durability and appearance.

Высокая теплопроводность алюминия делает его популярным в теплообменниках, радиаторах и электронных устройствах, где необходимо эффективное рассеивание тепла. Similarly, его электропроводность, хотя и ниже, чем у меди, всё же достаточна для многих electrical applications, such as in power transmission lines.

Эстетически алюминиевые листы могут быть обработаны до зеркального блеска или матовой поверхности, что широко используется в архитектуре и дизайне. Например, многие modern buildings feature aluminum facades that are not only functional but also visually appealing.

Все эти преимущества contribute to the ease of mechanical processing, as a material that is inherently ductile and malleable is easier to work with. However, let's dive deeper into the specifics of each processing method.

Резка алюминиевых листов

Резка — это один из самых common processes in mechanical processing of aluminum sheets. It can be done using various methods, such as shearing, laser cutting, waterjet cutting, or plasma cutting. Aluminum is relatively soft compared to metals like steel, which makes it easier to cut with less force and wear on tools.

Shearing is a mechanical method where a blade is used to cut the sheet. Aluminum's ductility allows for clean cuts with minimal burrs, especially when using sharp blades and proper equipment. For example, in industrial settings, hydraulic shears can easily handle aluminum sheets up to several millimeters thick without issues.

Laser cutting is highly precise and efficient for aluminum. The laser beam melts the material, and the high reflectivity of aluminum can be a challenge, but modern CO2 or fiber lasers are designed to handle it effectively. This method produces smooth edges and is ideal for intricate designs, such as in signage or electronic enclosures.

Waterjet cutting uses a high-pressure stream of water mixed with abrasive particles to cut through the material. It is cold-cutting process, so it doesn't generate heat that could alter the properties of aluminum. This makes it suitable for thick sheets or heat-sensitive applications.

Plasma cutting is another option, particularly for thicker sheets. It uses a plasma torch to melt the metal and blow it away. While it can be faster, it may leave a rougher edge compared to laser cutting.

In general, aluminum sheets are easy to cut due to their softness, but factors like alloy type (e.g., 1000 series is softer than 6000 series) and thickness affect the ease. For instance, pure aluminum (1000 series) cuts very easily, while harder alloys might require more powerful equipment.

Гибка алюминиевых листов

Гибка — это процесс изгибания листа to form angles or curves. Aluminum's high ductility makes it excellent for bending without cracking, which is a common issue with brittle materials like some steels or cast iron.

In bending, the minimum bend radius is important to avoid failure. For aluminum, the bend radius can be as small as the thickness of the sheet for soft alloys, but harder alloys may require a larger radius. Tools like press brakes are commonly used, and aluminum's low springback (the tendency of the material to return to its original shape after bending) simplifies the process compared to steel.

For example, in the automotive industry, aluminum sheets are often bent to create body panels. The ease of bending allows for complex shapes without additional heat treatment, saving time and cost.

However, care must be taken to avoid over-bending, which can lead to work hardening and reduced ductility. Using proper dies and lubricants can enhance the process. Overall, aluminum sheets are very easy to bend, making them a preferred choice for applications requiring formed parts.

Фрезерование и сверление

Фрезерование involves removing material using rotary cutters to create shapes or features, while сверление is making holes. Aluminum is soft and has good machinability, which means it can be milled or drilled quickly with minimal tool wear.

For milling, high-speed steel or carbide tools are used. Aluminum's low cutting forces allow for high feed rates and speeds, increasing productivity. Chip formation is also favorable; aluminum produces discontinuous chips that are easy to manage, reducing the risk of tool clogging.

Drilling is straightforward with aluminum. Standard drill bits work well, and the material's softness means holes can be made precisely without excessive heat generation. Coolants are often used to improve surface finish and tool life, but they are not always necessary for thin sheets.

In CNC machining, aluminum is a favorite material due to its ease of processing. It can be machined to tight tolerances, which is essential in industries like aerospace for components such as brackets or housings.

The main challenge in milling and drilling aluminum is its tendency to gum up on tools if not properly managed, but this is easily mitigated with sharp tools and appropriate cutting parameters. Thus, aluminum sheets are highly amenable to these processes.

Сварка алюминиевых листов

Сварка is joining pieces together using heat. Aluminum can be welded using methods like TIG (Tungsten Inert Gas), MIG (Metal Inert Gas), or resistance welding, but it requires more skill than welding steel due to its high thermal conductivity and oxide layer.

The oxide layer on aluminum has a higher melting point than the base metal, so it must be removed before welding to avoid defects. This is typically done with chemical cleaners or mechanical abrasion.

TIG welding is precise and produces high-quality welds, ideal for thin sheets. It uses a non-consumable tungsten electrode and inert gas to protect the weld area. MIG welding is faster and better for thicker sheets, using a consumable wire electrode.

Despite the challenges, aluminum's weldability is good with proper technique. For instance, in shipbuilding, aluminum sheets are welded to create lightweight hulls. The ease of welding depends on the alloy; some series, like 5000 and 6000, weld better than others.

Post-weld heat treatment may be needed to relieve stresses and restore properties, but for many applications, it's not necessary. Overall, while welding aluminum requires attention to detail, it is certainly feasible and widely practiced.

Факторы, влияющие на лёгкость обработки

Several factors affect how easily aluminum sheets can be mechanically processed. The alloy composition is crucial; pure aluminum (1000 series) is very soft and easy to work with, while alloyed versions like 2000 series (with copper) are harder and may require more force.

Thickness also plays a role; thinner sheets are easier to cut and bend, but may be more prone to distortion during welding. Thicker sheets might need more powerful equipment.

The temper of the aluminum, such as O (annealed) or H (work-hardened), influences its properties. Annealed aluminum is softer and easier to process, while hardened tempers are stronger but less ductile.

Equipment and tool quality are important; using sharp, appropriate tools can make a significant difference. For example, dull blades in shearing can cause excessive burrs.

Operator skill cannot be overlooked; experienced workers can handle aluminum more efficiently, minimizing errors and waste.

Environmental factors, like temperature, can affect processing; aluminum's properties change slightly with temperature, but this is rarely an issue in controlled environments.

By considering these factors, one can optimize the processing of aluminum sheets for specific applications.

Практические применения и примеры

Алюминиевые листы используются в myriad applications due to their ease of processing. In construction, they are used for roofing, cladding, and windows because they are lightweight, corrosion-resistant, and easy to form on-site.

In transportation, cars and airplanes rely on aluminum for body panels and structures to reduce weight and improve fuel efficiency. For instance, the Boeing 787 Dreamliner uses extensive aluminum components that are easily machined and assembled.

In electronics, aluminum sheets are used for heat sinks and enclosures because they can be precisely milled and have good thermal properties.

Consumer goods, such as appliances and packaging, often feature aluminum due to its formability and aesthetic appeal. For example, aluminum cans are made from sheets that are deep-drawn easily.

These examples demonstrate that the ease of mechanical processing makes aluminum a versatile and cost-effective choice across industries.

Сравнение с другими материалами

Compared to other common materials like steel, copper, or plastics, aluminum stands out for its balance of properties. Steel is stronger but heavier and harder to process, requiring more energy for cutting and bending.

Copper has better conductivity but is heavier and more expensive, with poorer corrosion resistance without coating.

Plastics are lightweight and easy to mold, but they lack the strength and durability of metals, and their processing often involves injection molding rather than mechanical methods.

Aluminum offers a sweet spot: it's light, strong enough for many applications, and highly machinable. This makes it a preferred material where weight savings and ease of fabrication are priorities.

Советы по выбору и обработке

When selecting aluminum sheets for mechanical processing, consider the alloy and temper based on the application. For general purposes, 3003 or 5052 alloys are good choices due to their formability and strength.

Use sharp tools and maintain equipment regularly to ensure clean cuts and bends. For welding, choose alloys like 5356 or 4043 filler metals to match the base material.

Implement proper safety measures, such as wearing gloves and eye protection, as aluminum chips can be sharp.

For optimal results, consult with material suppliers or use simulation software to predict behavior during processing.

By following these tips, you can maximize the ease and efficiency of working with aluminum sheets.

Заключение

В заключение, алюминиевые листы легко поддаются механической обработке благодаря их пластичности, лёгкости и коррозионной стойкости. Processes like резка, гибка, фрезерование, and сварка are feasible with the right techniques and equipment. While challenges exist, such as the need for care in welding or tool selection, the overall ease makes aluminum a top choice in many industries. By understanding the factors involved and applying best practices, manufacturers can leverage aluminum's advantages to create innovative and efficient products. As technology advances, the processing of aluminum will only become easier, further solidifying its role in modern manufacturing.

This article has provided a comprehensive overview, but remember that practical experience is key. If you're new to working with aluminum, start with small projects to build confidence. Embrace the versatility of this remarkable material, and you'll find that aluminum sheets are indeed easy to mechanically process.