Почему тонкие алюминиевые листы становятся выбором профессионалов

В современном мире строительства, промышленности и дизайна выбор материалов играет ключевую роль в обеспечении эффективности, долговечности и экономической целесообразности проектов. Среди множества доступных опций тонкие алюминиевые листы выделяются как предпочтительный выбор для профессионалов в различных отраслях. Эта статья исследует причины, по которым эти листы завоевали такую популярность, охватывая их свойства, применение, преимущества и будущие тенденции. Мы углубимся в детали, чтобы предоставить всесторонний обзор, помогая читателям понять, почему алюминий, особенно в тонкой форме, стал незаменимым инструментом для экспертов.

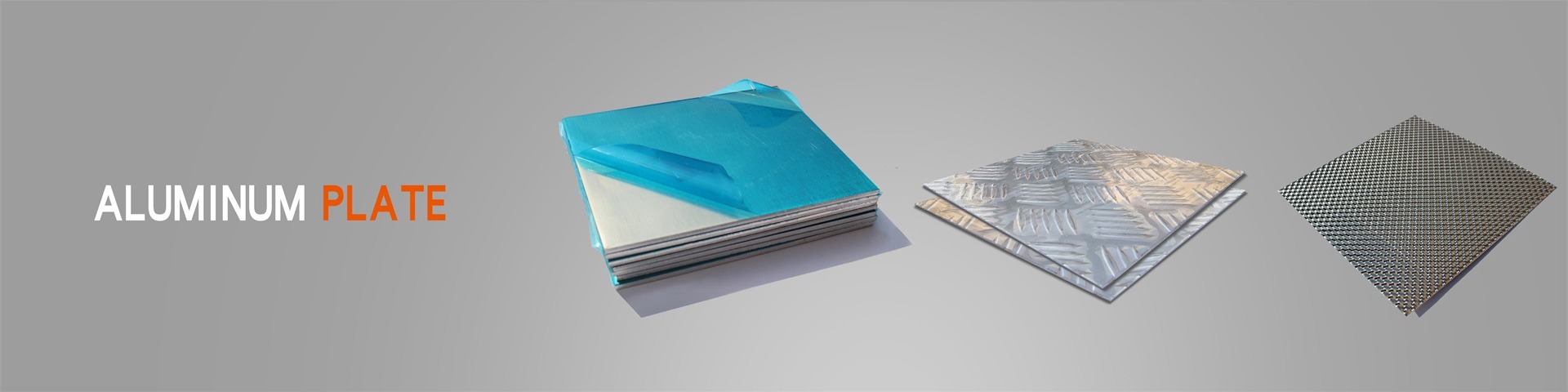

Введение в алюминиевые листы

Алюминий — это легкий, прочный и коррозионно-стойкий металл, который широко используется с начала 20 века. Тонкие алюминиевые листы, typically ranging from 0.2 mm to 6 mm in thickness, are produced through processes like rolling and annealing. These sheets offer a unique combination of properties that make them ideal for professional applications. Historically, aluminum was first isolated in the 1820s, but it wasn't until the development of the Hall-Héroult process in the late 19th century that it became commercially viable. Today, aluminum is the second most used metal after steel, with thin sheets being a critical component in industries such as construction, automotive, aerospace, and packaging.

The versatility of aluminum stems from its atomic structure and alloying capabilities. Pure aluminum is soft and malleable, but when alloyed with elements like copper, magnesium, or silicon, it gains strength and other desirable characteristics. Thin sheets are often made from alloys such as 1000 series (pure aluminum), 3000 series (manganese alloys), or 5000 series (magnesium alloys), each tailored for specific uses. For instance, alloy 5052 is known for its excellent corrosion resistance, making it suitable for marine environments, while alloy 6061 is valued for its strength and weldability in structural applications.

Professionals choose thin aluminum sheets because they provide an optimal balance between weight, strength, and cost. Unlike thicker materials, thin sheets are easier to handle, cut, and form, reducing labor costs and installation time. Moreover, aluminum's natural oxide layer protects it from rust, ensuring longevity without the need for extensive maintenance. This makes it a sustainable choice, as aluminum is highly recyclable—over 75% of all aluminum ever produced is still in use today. As we move into an era focused on sustainability and efficiency, the demand for thin aluminum sheets continues to grow, driven by innovations in manufacturing and design.

Преимущества тонких алюминиевых листов

Одним из главных преимуществ тонких алюминиевых листов является их легкость. Алюминий имеет плотность около 2.7 g/cm³, что примерно в три раза меньше, чем у стали. Это означает, что тонкие листы значительно снижают общий вес конструкций, что особенно важно в аэрокосмической и автомобильной промышленности, где каждый килограмм saved can lead to improved fuel efficiency and performance. For example, in aircraft design, the use of thin aluminum sheets in fuselages and wings helps reduce weight, allowing for longer flights and lower operational costs. Similarly, in automotive applications, lightweight body panels contribute to better fuel economy and reduced emissions, aligning with global environmental regulations.

Коррозионная стойкость — another key advantage. Aluminum naturally forms a protective oxide layer when exposed to air, which prevents further oxidation and degradation. This makes thin aluminum sheets ideal for outdoor applications, such as roofing, siding, and cladding, where they can withstand harsh weather conditions without rusting. Unlike steel, which requires galvanization or painting for protection, aluminum often needs minimal coating, reducing maintenance costs over time. In marine environments, alloys like 5083 or 6061 are preferred for their resistance to saltwater corrosion, ensuring durability in ships and offshore structures.

Гибкость и обрабатываемость тонких алюминиевых листов make them easy to work with in various professional settings. They can be cut, bent, punched, and welded using standard tools, allowing for custom designs and rapid prototyping. This malleability is enhanced by the thin gauge, which requires less force to shape, reducing energy consumption during fabrication. In the construction industry, this means faster installation times and the ability to create complex architectural features, such as curved facades or intricate details. Additionally, aluminum's thermal and electrical conductivity make it suitable for applications in electronics and heat exchangers, where thin sheets are used as heat sinks or shielding components.

Экономическая эффективность is a significant factor driving professional adoption. While the initial cost of aluminum might be higher than some materials like steel, the long-term savings in maintenance, transportation, and energy efficiency often justify the investment. Thin sheets, in particular, reduce material waste during production and installation, as they can be precision-cut to size. Furthermore, aluminum's recyclability means that scrap can be melted down and reused indefinitely without loss of quality, contributing to a circular economy. This sustainability aspect is increasingly important for professionals aiming to meet green building standards and reduce their environmental footprint.

Применение в строительстве

В строительной отрасли тонкие алюминиевые листы используются extensively for roofing, wall cladding, and interior design. Their lightweight nature simplifies handling and installation, especially in high-rise buildings where weight reduction is critical for structural integrity. For instance, aluminum roofing sheets are popular in commercial and residential projects due to their durability and aesthetic appeal. They can be coated with various finishes, such as PVDF (polyvinylidene fluoride) or anodized, to enhance color retention and weather resistance. This allows architects to achieve modern, sleek designs while ensuring longevity.

Another common application is in curtain walls and facades. Thin aluminum sheets are often used as panels in these systems, providing a barrier against elements while allowing for creative expression. The material's ability to be formed into complex shapes enables the creation of unique building exteriors that stand out in urban landscapes. Moreover, aluminum's reflectivity can improve energy efficiency by reducing heat gain in buildings, leading to lower cooling costs. In regions with extreme climates, such as the Middle East or Northern Europe, this thermal performance is a major advantage for professionals designing sustainable structures.

Interior applications include ceilings, partitions, and decorative elements. Thin aluminum sheets can be perforated for acoustic control or etched for artistic patterns, adding functionality and beauty to spaces. In retail environments, for example, aluminum is used for signage and displays due to its modern look and ease of customization. The fire resistance of aluminum (it does not burn and melts at high temperatures) also makes it a safe choice for interior use, complying with building codes and safety standards. Professionals appreciate these versatile applications, as they allow for innovation while maintaining practical benefits.

Infrastructure projects, such as bridges and tunnels, also benefit from thin aluminum sheets. They are used in guardrails, lighting fixtures, and ventilation systems, where corrosion resistance and lightweight are essential. For instance, in coastal areas, aluminum components avoid the rust issues common with steel, extending the life of infrastructure. The ease of maintenance—often requiring only occasional cleaning—reduces long-term costs for municipalities and contractors. As urbanization accelerates globally, the demand for durable, low-maintenance materials like thin aluminum sheets is expected to rise, solidifying their role in professional construction practices.

Применение в промышленности

В промышленном секторе тонкие алюминиевые листы находят применение в automotive, aerospace, packaging, and electronics. In the automotive industry, they are used for body panels, heat shields, and battery enclosures in electric vehicles (EVs). The push towards electrification has increased the demand for lightweight materials to offset the weight of batteries, and aluminum sheets excel in this regard. Brands like Tesla and BMW incorporate aluminum extensively in their designs to improve range and performance. Additionally, the formability of thin sheets allows for efficient stamping and assembly lines, reducing production time and costs.

In aerospace, thin aluminum sheets are critical for aircraft skins, wings, and interior components. Alloys such as 2024 and 7075 are preferred for their high strength-to-weight ratio, ensuring safety and efficiency in flight. The ability to withstand cyclic loading and extreme temperatures makes aluminum indispensable in this field. Maintenance is simplified due to the material's corrosion resistance, reducing downtime for repairs. As air travel grows, advancements in aluminum alloys and manufacturing techniques, such as additive manufacturing with aluminum powders, are expanding the possibilities for even thinner, stronger sheets in future aircraft designs.

Упаковка is another major area where thin aluminum sheets shine. They are used for beverage cans, food containers, and pharmaceutical packaging due to their impermeability to light, oxygen, and moisture, which preserves product quality. The thin gauge minimizes material use, making it cost-effective and environmentally friendly. Recycling rates for aluminum packaging are high, often exceeding 90% in developed countries, which appeals to professionals focused on sustainability. In the electronics industry, aluminum sheets serve as heat sinks in devices like smartphones and computers, dissipating heat efficiently to prevent overheating. Their electrical conductivity also makes them suitable for shielding against electromagnetic interference (EMI).

General manufacturing uses include machinery parts, conveyor systems, and tooling. Thin aluminum sheets can be machined into precise components, offering good dimensional stability and wear resistance. In chemical processing, aluminum's resistance to certain acids and alkalis makes it useful for tanks and pipes. Professionals in these fields value the material's versatility and reliability, which contribute to operational efficiency and product quality. As Industry 4.0 introduces smarter manufacturing processes, the integration of aluminum sheets with technologies like IoT sensors for monitoring conditions is becoming more common, enhancing their utility.

Экологические аспекты

Экологическая устойчивость является ключевым фактором в выборе материалов сегодня, и тонкие алюминиевые листы предлагают значительные преимущества. Алюминий является одним из наиболее перерабатываемых материалов в мире; его recycling requires only 5% of the energy needed to produce primary aluminum from bauxite ore. This energy savings translates to reduced greenhouse gas emissions, making aluminum a green choice for professionals committed to reducing their carbon footprint. Thin sheets, due to their lightweight, further contribute to lower transportation emissions, as more material can be shipped per load compared to heavier alternatives.

The production process of aluminum has also seen improvements in sustainability. Modern smelters use renewable energy sources, such as hydropower, to minimize environmental impact. Additionally, advancements in rolling technology allow for thinner gauges with less material waste. Life cycle assessments (LCA) consistently show that aluminum products, including thin sheets, have a lower environmental impact over their lifetime compared to many other metals. For example, in building applications, aluminum's durability means fewer replacements and less resource consumption over decades of use.

Professionals are increasingly adopting aluminum as part of green building certifications like LEED (Leadership in Energy and Environmental Design) or BREEAM (Building Research Establishment Environmental Assessment Method). The use of recycled content in aluminum sheets can earn points towards these certifications, encouraging sustainable practices. Moreover, aluminum's reflectivity contributes to urban heat island mitigation by reflecting sunlight, reducing the need for air conditioning in cities. This aligns with global efforts to combat climate change and promote resilient infrastructure.

Challenges remain, such as the energy-intensive nature of primary aluminum production, but industry initiatives are addressing these through innovation. For instance, the Aluminium Stewardship Initiative (ASI) certifies responsible sourcing and production practices. Professionals can choose ASI-certified aluminum to ensure ethical and environmental standards are met. As consumer awareness grows, the demand for sustainable materials will continue to drive the preference for thin aluminum sheets in professional circles, reinforcing their role in a circular economy.

Будущие тенденции и инновации

Будущее тонких алюминиевых листов looks promising, with ongoing innovations enhancing their properties and applications. One emerging trend is the development of nano-coated aluminum sheets, which offer superior corrosion resistance, self-cleaning properties, or enhanced thermal performance. These coatings, often based on nanotechnology, can make aluminum even more durable and versatile for extreme environments. For example, in the renewable energy sector, such sheets could be used in solar panel frames or wind turbine components, where longevity and efficiency are paramount.

Additive manufacturing, or 3D printing, is another area where thin aluminum sheets are evolving. While traditional sheets are cut from rolled stock, 3D printing allows for the creation of complex, lightweight structures directly from aluminum powder. This technology enables customization and reduces waste, appealing to professionals in aerospace, medical devices, and prototyping. As 3D printing becomes more accessible, we may see thinner, stronger aluminum components that were previously impossible to manufacture.

Advancements in alloy development are also on the horizon. Researchers are creating new aluminum alloys with improved strength, ductility, or conductivity. For instance, aluminum-lithium alloys offer even lighter weight for aerospace applications, while scandium-doped alloys enhance weldability and strength. These innovations will expand the use of thin sheets in high-performance fields, ensuring that professionals have access to cutting-edge materials.

The integration of smart technologies is set to transform how aluminum sheets are used. Embedded sensors in thin sheets could monitor structural health in real-time, providing data on stress, temperature, or corrosion. This is particularly valuable in critical infrastructure like bridges or aircraft, where preventative maintenance can avoid failures. Additionally, the rise of the Internet of Things (IoT) may lead to "smart" aluminum products that interact with other systems, optimizing performance and sustainability.

As global priorities shift towards sustainability and efficiency, the demand for thin aluminum sheets is expected to grow. Professionals will continue to favor them for their combination of lightweight, durability, and eco-friendliness. By staying abreast of these trends, industries can leverage aluminum to meet future challenges, from climate change to technological advancement.

Заключение

В заключение, тонкие алюминиевые листы заслужили свое место作为专业首选的原因是多方面的。他们的轻质、耐腐蚀性、可加工性和经济性使他们在建筑、工业和其他领域不可或缺。随着可持续性和创新成为全球焦点,铝的回收能力和环境效益进一步巩固了其吸引力。从历史背景到未来趋势,这篇文章展示了为什么专业人士继续选择薄铝板来实现他们的项目。

无论是设计摩天大楼、制造电动汽车,还是创建可持续包装,薄铝板都提供了无与伦比的 versatility and performance. As technology advances, we can expect even more innovative applications, making aluminum an enduring choice for experts worldwide. By understanding these factors, professionals can make informed decisions that enhance efficiency, reduce costs, and contribute to a greener future.

In summary, the adoption of thin aluminum sheets is not just a trend but a strategic move towards better, more sustainable practices. Their proven track record and ongoing innovations ensure that they will remain a top choice for professionals across various industries for years to come.