Тяжелые алюминиевые плиты ключ к прочности и долговечности конструкций

В современном мире строительства и инженерии поиск материалов, сочетающих высокую прочность, легкость и устойчивость к коррозии, остается одной из ключевых задач. Среди множества вариантов тяжелые алюминиевые плиты выделяются как универсальное решение, способное значительно повысить надежность и срок службы различных конструкций. Алюминий, будучи вторым по распространенности металлом на Земле, обладает уникальными свойствами, которые делают его идеальным кандидатом для использования в ответственных проектах. Однако, когда речь заходит о тяжелых плитах, многие до сих пор ассоциируют прочность исключительно со сталью или бетоном, недооценивая потенциал алюминиевых сплавов. Эта статья aims to развеять такие мифы и подробно рассмотреть, почему тяжелые алюминиевые плиты являются незаменимым элементом в создании durable и sustainable структур.

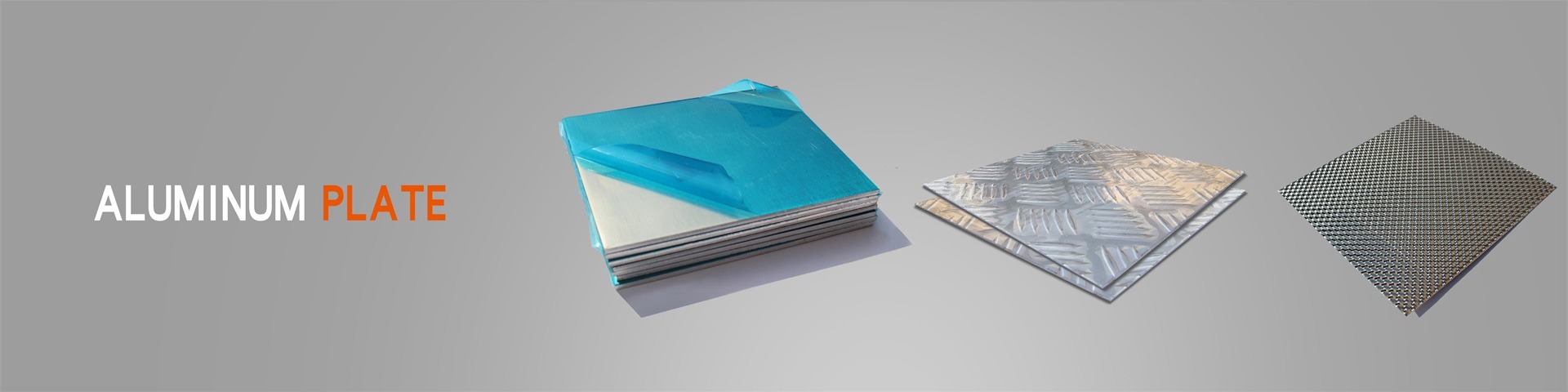

Прежде всего, стоит обратиться к физическим и химическим характеристикам алюминия. Алюминий имеет низкую плотность около 2,7 г/см³, что примерно в три раза меньше, чем у стали. Это означает, что конструкции из алюминия значительно легче, что снижает нагрузки на фундаменты и упрощает монтаж. Однако, когда мы говорим о 'тяжелых' плитах, это не противоречит легкости материала. Термин 'тяжелые' здесь относится к толщине и массе плит, которые designed to withstand high stresses. Благодаря легированию с такими элементами, как медь, магний, кремний или цинк, алюминиевые сплавы могут достигать прочности, comparable to некоторых марок стали. Например, сплав 6061, commonly used in structural applications, имеет предел прочности на растяжение до 310 MPa, while сплав 7075, known for its high strength, can exceed 570 MPa. Эти значения делают алюминиевые плиты capable of handling significant mechanical loads without deformation.

Коррозионная стойкость – another critical advantage. Unlike steel, which requires регулярное покраска or galvanization to prevent rust, алюминий naturally forms a protective oxide layer when exposed to air. This layer is thin, adherent, and self-healing, meaning that even if scratched, it reforms quickly, providing continuous protection against environmental factors such as moisture, salt, and chemicals. This property is particularly valuable in harsh environments like coastal areas or industrial zones, where corrosion can compromise structural integrity over time. For instance, in bridge construction, the use of aluminum plates can reduce maintenance costs and extend the lifespan of the structure by decades.

The durability of aluminum plates is further enhanced by their fatigue resistance. Fatigue failure occurs when a material is subjected to repeated loading and unloading cycles, leading to crack propagation and eventual fracture. Aluminum alloys exhibit excellent fatigue performance due to their fine grain structure and ability to absorb energy. This makes them ideal for applications involving dynamic loads, such as in aerospace, automotive, or seismic-resistant buildings. Studies have shown that aluminum components can withstand millions of cycles without significant degradation, ensuring long-term reliability.

In terms of sustainability, aluminum is highly recyclable without loss of quality. Recycling aluminum requires only 5% of the energy needed to produce primary aluminum from bauxite ore, making it an environmentally friendly choice. The use of heavy aluminum plates in construction contributes to green building practices by reducing the carbon footprint and promoting circular economy principles. Moreover, the light weight of aluminum reduces transportation emissions during delivery to construction sites.

Practical applications of heavy aluminum plates are vast and varied. In the construction industry, they are used for load-bearing elements in buildings, bridges, and towers. For example, in skyscrapers, aluminum plates can be employed in facades, floors, and support structures to reduce overall weight while maintaining strength. In infrastructure projects, such as tunnels or dams, aluminum plates serve as lining or reinforcement due to their corrosion resistance and ease of installation. The maritime sector also benefits from aluminum's properties; shipbuilders use thick aluminum plates for hulls and superstructures to enhance buoyancy and resist saltwater corrosion.

Furthermore, in the transportation sector, heavy aluminum plates are crucial for manufacturing railway cars, trucks, and trailers. Their high strength-to-weight ratio improves fuel efficiency and payload capacity, while their durability ensures safety over long operational lifetimes. In renewable energy, aluminum plates are used in solar panel frames and wind turbine components, where resistance to weathering and light weight are essential.

Despite these advantages, there are challenges to consider. The initial cost of aluminum can be higher than that of steel, but this is often offset by lower life-cycle costs due to reduced maintenance and longer service life. Additionally, welding and fabrication of aluminum require specialized techniques to avoid issues like porosity or cracking, but advancements in technology have made these processes more accessible and reliable.

In conclusion, heavy aluminum plates represent a smart investment for any project prioritizing strength, durability, and sustainability. Their unique combination of properties – light weight, high strength, corrosion resistance, and recyclability – makes them a key material in modern engineering. As industries continue to evolve towards more efficient and eco-friendly solutions, the role of aluminum will only grow, solidifying its position as a cornerstone of durable constructions. By choosing aluminum, engineers and architects not only ensure the longevity of their designs but also contribute to a more sustainable future.

To delve deeper, let's explore the historical context. Aluminum was first isolated in the 19th century and quickly gained popularity due to its novelty and properties. Initially, it was expensive and used primarily for decorative purposes, but with the development of the Hall-Héroult process in 1886, production costs dropped, making it accessible for industrial applications. World War II accelerated its use in aviation, where weight savings were critical. Post-war, aluminum became ubiquitous in various sectors, from packaging to construction. The evolution of aluminum alloys has been driven by continuous research, leading to grades tailored for specific needs, such as the 7xxx series for high strength or the 5xxx series for excellent corrosion resistance.

In modern times, the construction industry has embraced aluminum for its versatility. For instance, the Burj Khalifa in Dubai utilizes aluminum in its cladding and structural elements to reduce weight and withstand the desert environment. Similarly, the Millau Viaduct in France features aluminum components to minimize load and enhance aesthetic appeal. These examples underscore how heavy aluminum plates can be integrated into iconic projects to achieve both functional and visual goals.

Looking ahead, innovations in aluminum technology promise even greater advancements. Nanostructuring and composite materials are being explored to enhance mechanical properties further. Additive manufacturing, or 3D printing, allows for the creation of complex aluminum parts with reduced waste. These developments will expand the applications of heavy aluminum plates, enabling more innovative and efficient designs.

In summary, the evidence is clear: heavy aluminum plates are indeed a key to strength and durability in constructions. Their benefits extend beyond mere performance to encompass environmental and economic advantages. By understanding and leveraging these properties, the engineering community can build structures that stand the test of time while adhering to sustainable principles. It is time to fully recognize and utilize the potential of aluminum in shaping the future of construction and beyond.