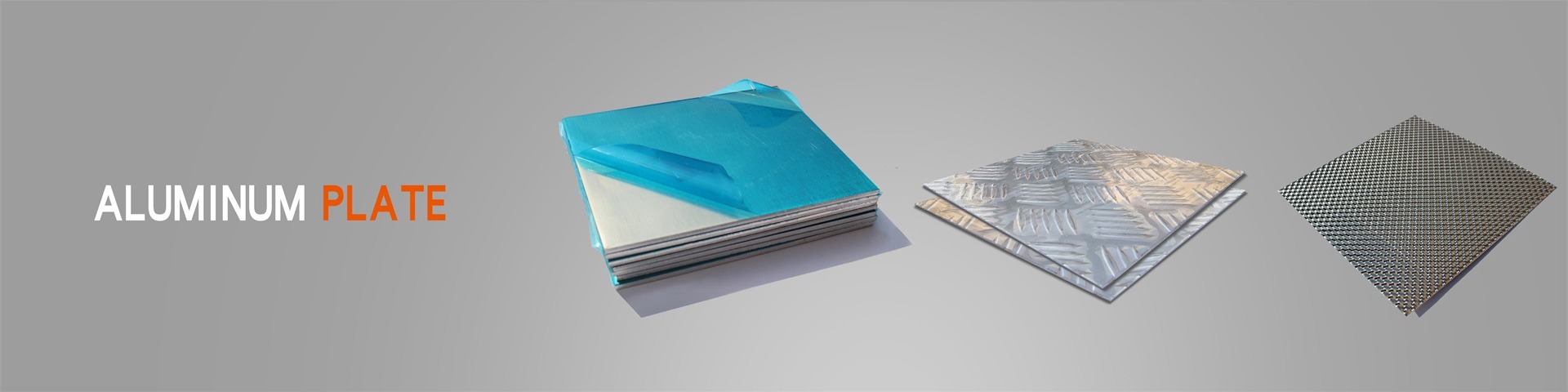

Пять ребер алюминиевая плита прочность для ваших проектов

В современном мире строительства и инженерии выбор материалов играет ключевую роль в обеспечении долговечности, надежности и экономической эффективности проектов. Алюминиевые плиты с пятью ребрами представляют собой инновационное решение, которое сочетает в себе легкость, коррозионную стойкость и выдающуюся прочность. В этой статье мы глубоко погрузимся в особенности этих плит, их преимущества, применение и то, как они могут преобразить ваши проекты, обеспечивая превосходные результаты.

Введение в алюминиевые плиты с пятью ребрами

Алюминий, как материал, известен своими уникальными свойствами: он легкий, прочный, устойчивый к коррозии и легко обрабатывается. Плиты с пятью ребрами – это специализированный тип алюминиевых конструкций, где дополнительные ребра жесткости увеличивают механическую прочность без значительного увеличения веса. Это делает их идеальными для применений, требующих высокой нагрузки и устойчивости, таких как строительство мостов, авиационная промышленность, автомобилестроение и даже в бытовых проектах, например, в мебели или декоративных элементах.

Исторически алюминий начал широко использоваться в XX веке, но с развитием технологий производства, такие как экструзия и литье, появились более сложные формы, включая плиты с ребрами. Пять ребер – это не случайное число; оно оптимизировано для распределения напряжений и минимизации деформаций под нагрузкой. В сравнении с традиционными плоскими плитами или плитами с меньшим количеством ребер, пятиреберные конструкции предлагают улучшенную устойчивость к изгибу и кручению, что критично для динамических сред.

В этой статье мы рассмотрим все аспекты этих плит: от сырья и производства до практических применений и будущих тенденций. Мы также предоставим сравнительный анализ с другими материалами, такими как сталь или композиты, чтобы помочь вам сделать informed решение для ваших проектов. Независимо от того, являетесь ли вы инженером, архитектором или DIY-энтузиастом, эта информация будет invaluable для достижения успеха.

Технические характеристики и преимущества

Алюминиевые плиты с пятью ребрами обладают рядом технических характеристик, которые делают их standout выбором. Во-первых, прочность на разрыв и yield strength этих плит может варьироваться в зависимости от сплава и обработки. Common сплавы, такие как 6061 или 7075, offer высокую прочность при относительно low весе. For example, сплав 6061 имеет предел прочности на разрыв около 310 MPa, в то время как 7075 может достигать 570 MPa, что сравнимо с некоторыми сталями, но при значительно меньшем весе.

Ребра в конструкции служат для увеличения момента инерции, что напрямую влияет на жесткость плиты. Это означает, что под нагрузкой плита менее склонна к прогибу или вибрации, что важно для applications, где точность и стабильность critical, таких как aerospace components или precision machinery. Additionally, алюминий naturally resistant to corrosion due to its oxide layer, but further treatments like anodizing can enhance this property, making these plates suitable for outdoor or marine environments.

Another key advantage is thermal and electrical conductivity. Aluminum is an excellent conductor, which can be beneficial in projects involving heat dissipation or electrical applications, though insulation might be needed in some cases. The five-rib design also allows for better weight distribution, reducing stress concentrations and extending the lifespan of the structure.

In terms of sustainability, aluminum is highly recyclable, with up to 95% of it being reusable without loss of properties. This makes it an eco-friendly choice compared to many other metals. Moreover, the lightweight nature reduces transportation costs and energy consumption during installation, contributing to overall project efficiency.

Методы производства

Production of aluminum plates with five ribs typically involves processes like extrusion or casting. Extrusion is common for creating complex profiles: aluminum billets are heated and forced through a die to form the desired shape, including the ribs. This method allows for high precision and consistency, making it ideal for mass production. After extrusion, plates may undergo heat treatment (e.g., T6 temper for 6061 alloy) to enhance strength and hardness.

Casting is another option, especially for larger or custom shapes, but it might introduce more defects and require additional machining. Advances in technology, such as computer-aided design (CAD) and finite element analysis (FEA), help optimize the rib design for specific loads, ensuring maximum performance. Quality control measures, including non-destructive testing like ultrasonic inspection, are crucial to detect any imperfections that could compromise integrity.

The choice of production method depends on factors like volume, cost, and application requirements. For instance, extrusion is cost-effective for standardized profiles, while casting might be better for one-off projects. Regardless, modern manufacturing ensures that these plates meet strict industry standards, such as those from ASTM or ISO, guaranteeing reliability and safety.

Применение в различных отраслях

Aluminum plates with five ribs find applications across numerous industries due to their versatility. In construction, they are used for structural elements like beams, columns, or facade systems, where their strength-to-weight ratio allows for lighter frameworks without sacrificing durability. For example, in bridge construction, these plates can reduce dead load, enabling longer spans and better seismic performance.

In aerospace, weight is paramount, and these plates are ideal for aircraft frames, wings, or interior components. Their resistance to fatigue and corrosion ensures longevity in harsh environments. Similarly, in automotive industry, they are used in chassis, body panels, or battery enclosures for electric vehicles, contributing to fuel efficiency and safety.

Marine applications benefit from the corrosion resistance, making these plates suitable for boat hulls, decks, or offshore structures. In consumer goods, they appear in furniture, sporting equipment, or electronic enclosures, where aesthetics and functionality are balanced. Even in art and design, the sleek appearance of aluminum can be leveraged for modern sculptures or architectural features.

Case studies show that projects using these plates often report reduced maintenance costs and improved performance. For instance, a recent infrastructure project in a coastal area utilized five-rib aluminum plates for walkways, resulting in minimal corrosion over years compared to steel alternatives.

Сравнительный анализ с другими материалами

When comparing aluminum plates with five ribs to other materials, several factors come into play. Steel, for example, offers higher ultimate strength but is much heavier and prone to corrosion without protection. This means that for weight-sensitive applications, aluminum is superior, as it can achieve similar strength with less mass, reducing overall costs in transportation and support structures.

Composites like carbon fiber are even lighter and stronger but are more expensive and difficult to repair. Aluminum strikes a balance between cost, performance, and ease of fabrication. For instance, while carbon fiber might be used in high-end aerospace, aluminum is more accessible for general engineering projects.

Wood or plastics are cheaper but lack the durability and strength of metal. In terms of environmental impact, aluminum's recyclability gives it an edge over many alternatives. However, the initial energy cost of producing aluminum is high, but this is offset by its long lifecycle and reuse potential.

Overall, five-rib aluminum plates provide a robust solution that is competitive across multiple metrics, making them a go-to choice for many professionals.

Рекомендации по выбору и использованию

Selecting the right aluminum plate with five ribs involves considering several factors. First, determine the load requirements: calculate the expected stresses and choose an alloy with appropriate strength properties. For dynamic loads, fatigue resistance is key, so alloys like 7075 might be preferred over 6061.

Consider the environment: if exposed to corrosive elements, opt for coated or anodized versions. Size and thickness should match the application; thicker plates offer more strength but add weight. Use engineering software or consult with suppliers to model the behavior under load.

During installation, ensure proper fastening techniques to avoid stress concentrations. Regular maintenance, such as cleaning and inspection, can prolong life. For DIY projects, start with smaller pieces to practice cutting and drilling, as aluminum can be soft and prone to galling.

Cost is another factor; while aluminum might be more expensive upfront than some materials, its longevity and reduced maintenance often make it cost-effective in the long run. Always source from reputable manufacturers to guarantee quality and compliance with standards.

Будущие тенденции и инновации

The future of aluminum plates with five ribs looks promising with ongoing innovations. Advances in alloy development are creating stronger and lighter materials, such as aluminum-lithium alloys, which could further enhance performance in aerospace and automotive sectors.

<3>Additive manufacturing, or 3D printing, is beginning to be applied to metal parts, allowing for custom rib designs that are optimized for specific loads without the constraints of traditional extrusion. This could lead to more efficient and tailored solutions for unique projects.Sustainability trends are driving the use of recycled aluminum, reducing the carbon footprint. Smart materials with embedded sensors for health monitoring are also emerging, enabling real-time assessment of structural integrity.

As global demands for efficiency and sustainability grow, these plates will continue to evolve, offering even greater benefits for a wide range of applications. Staying updated with industry trends will help you leverage the latest advancements in your projects.

Заключение

В заключение, алюминиевые плиты с пятью ребрами представляют собой выдающееся решение для различных проектов, сочетая прочность, легкость и универсальность. От строительства до аэрокосмической отрасли, их преимущества делают их preferred choice для инженеров и designers. By understanding their properties, production methods, and applications, you can make informed decisions that enhance the success and sustainability of your endeavors.

We encourage you to explore these plates in your next project and experience the difference they can make. For more information, consult with experts or refer to technical datasheets to ensure optimal results.