Совершенство алюминиевой поверхности для современных фасадов

В современной архитектуре фасады играют ключевую роль не только в эстетическом восприятии зданий, но и в их функциональности, энергоэффективности и долговечности. Среди множества материалов, используемых для облицовки фасадов, алюминий выделяется своим уникальным сочетанием свойств: легкостью, прочностью, коррозионной стойкостью и универсальностью дизайна. В этой статье мы подробно рассмотрим, почему алюминиевые поверхности становятся идеальным выбором для современных фасадов, охватывая технические аспекты, экологические преимущества, инновационные применения и практические рекомендации. От исторического контекста до будущих трендов, мы погрузимся в мир алюминиевых фасадов, демонстрируя, как этот материал способен преобразовать городской ландшафт и повысить качество жизни.

Исторический обзор: эволюция алюминия в архитектуре

Алюминий, как материал, был открыт в начале XIX века, но его широкое применение в архитектуре началось лишь в середине XX века, благодаря развитию технологий производства и обработки. Первоначально алюминий использовался в основном в авиационной и военной промышленности из-за его легкости и прочности. Однако, с ростом урбанизации и потребности в современных, эффективных зданиях, архитекторы обратили внимание на потенциал алюминия для фасадных систем. В 1950-х годах появились первые примеры использования алюминиевых панелей в коммерческих зданиях, таких как небоскребы в США и Европе. Эти ранние применения often сопровождались проблемами, такими как коррозия при неправильной обработке, но быстрые инновации в покрытиях и сплавах решили эти issues. К 1970-м годам алюминиевые фасады стали символом модернизма и технологического прогресса, а к XXI веку они эволюционировали в высокотехнологичные системы, интегрирующие умные функции и устойчивые решения. Сегодня алюминий является одним из самых востребованных материалов в global строительстве, с ежегодным ростом рынка на 5-7%, что подчеркивает его enduring appeal.

Преимущества алюминиевых поверхностей: почему они идеальны для фасадов

Алюминиевые поверхности предлагают множество преимуществ, которые делают их превосходным выбором для современных фасадов. Во-первых, легкость материала значительно reduces нагрузку на несущие конструкции здания, позволяя проектировать более высокие и сложные формы без компромиссов в безопасности. Средняя плотность алюминия составляет около 2,7 г/см³, что в три раза меньше, чем у стали, что упрощает монтаж и снижает costs транспортировки и установки. Во-вторых, алюминий обладает exceptional коррозионной стойкостью благодаря natural oxide layer, который защищает его от воздействия влаги, UV radiation и химических загрязнителей. Это особенно важно в urban environments, где фасады подвергаются агрессивным атмосферным conditions. Дополнительно, алюминиевые поверхности могут быть обработаны с помощью анодирования или powder coating, что enhances их durability and provides a wide range of colors and finishes—from matte to glossy, metallic to wood-effect. Это позволяет архитекторам реализовывать креативные дизайнерские идеи, создавая уникальные visual identities для зданий. Кроме того, алюминий is 100% recyclable, with a recycling rate of over 90% in the construction industry, making it an eco-friendly choice that supports circular economy principles. The energy required to recycle aluminum is only 5% of that needed for primary production, significantly reducing carbon footprint. In terms of thermal performance, aluminum facades can be integrated with insulation materials to improve energy efficiency, reducing heating and cooling costs by up to 30%. For example, composite aluminum panels often include core materials like polyethylene or mineral wool, which enhance thermal break properties. Overall, these advantages make aluminum surfaces not only practical but also sustainable and cost-effective over the long term.

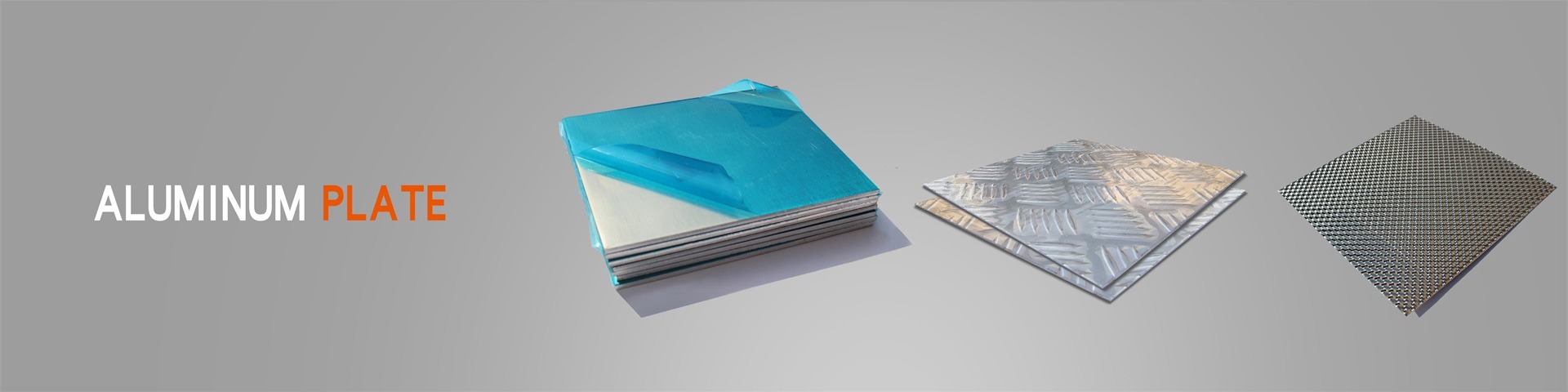

Технологии производства и обработки алюминия для фасадов

Современные технологии производства и обработки алюминия играют crucial role в achieving high-quality facade surfaces. The process begins with the extraction of bauxite ore, which is refined into alumina and then smelted to produce primary aluminum. However, for facade applications, secondary aluminum from recycling is increasingly used due to its lower environmental impact. Once the aluminum is produced, it undergoes various forming processes such as extrusion, rolling, or casting to create sheets, profiles, or panels tailored for facades. Extrusion is particularly popular for creating complex shapes with consistent cross-sections, ideal for window frames and curtain wall systems. For surface treatment, anodizing is a common method that involves electrolytic passivation to thicken the natural oxide layer, resulting in a hard, durable finish that resists scratching and fading. Anodized aluminum can achieve colors through dyeing or integral coloring processes, offering aesthetic versatility. Powder coating is another widely used technique where a dry powder is applied electrostatically and then cured under heat to form a tough, uniform layer. This method provides excellent resistance to chipping, abrasion, and UV radiation, and it allows for a vast palette of colors and textures—including metallic, pearlescent, and textured effects. Additionally, advancements in digital printing technology enable direct printing of patterns or images onto aluminum surfaces, opening up new possibilities for custom designs. For composite materials, aluminum composite panels (ACP) are manufactured by bonding two thin aluminum sheets to a non-aluminum core, such as polyethylene or fire-resistant mineral core. These panels combine the strength and lightness of aluminum with improved insulation and acoustic properties. Quality control during production involves rigorous testing for mechanical properties, coating adhesion, and color consistency to ensure longevity and performance. Innovations like nano-coatings are also emerging, providing self-cleaning surfaces that repel dirt and water, reducing maintenance needs. Overall, these technologies ensure that aluminum surfaces meet the high standards required for modern facades in terms of durability, aesthetics, and functionality.

Дизайн и эстетика: как алюминиевые фасады преобразуют архитектуру

Дизайн фасадов на основе алюминия offers unparalleled flexibility, enabling architects to create visually striking and innovative buildings. The material's malleability allows for the formation of curvilinear shapes, sharp angles, and intricate details that would be challenging with other materials. For instance, parametric design—using algorithms to generate complex geometries—is easily achievable with aluminum systems, as seen in iconic projects like the Heydar Aliyev Center in Baku by Zaha Hadid Architects, where flowing, organic forms are realized through custom-fabricated aluminum panels. Color and finish options are virtually limitless; anodized aluminum can produce subtle, metallic hues that change with light conditions, while powder coatings offer bold, solid colors or mimic materials like wood, stone, or concrete. This versatility supports branding and contextual integration, allowing buildings to stand out or blend into their surroundings as desired. In urban settings, aluminum facades contribute to the skyline with reflective surfaces that interact with sunlight, creating dynamic visual effects throughout the day. Moreover, the use of perforated aluminum panels introduces functionality alongside aesthetics; these panels can provide shade, natural ventilation, and privacy while adding texture and depth to the facade. For example, perforations can be designed in patterns that cast interesting shadows or display digital art when backlit. Sustainability-driven design often incorporates aluminum facades with green elements, such as integrated photovoltaic cells or vertical gardens, enhancing both appearance and environmental performance. Case studies abound: the Burj Khalifa in Dubai utilizes aluminum in its cladding for its lightweight and reflective properties, contributing to its iconic silhouette. Similarly, modern office buildings in cities like London and Tokyo employ aluminum curtain walls to achieve sleek, minimalist looks that signify corporate identity and technological advancement. The aesthetic appeal of aluminum is not just skin-deep; it supports holistic design approaches that balance form, function, and sustainability, making it a favorite among contemporary architects seeking to push boundaries and create memorable structures.

Энергоэффективность и экологичность: зеленые аспекты алюминиевых фасадов

В era of climate change and resource scarcity, the energy efficiency and environmental sustainability of building materials are paramount. Aluminum facades excel in this regard due to their inherent properties and potential for integration with green technologies. Firstly, aluminum's high reflectivity helps in reducing solar heat gain, which can lower cooling loads in buildings by up to 20–30%. This is particularly beneficial in hot climates, where reflective aluminum surfaces can significantly cut energy consumption for air conditioning. When combined with thermal break technology—where insulating barriers are inserted between inner and outer aluminum layers—the overall U-value of the facade is improved, enhancing insulation and reducing heat loss in colder regions. For instance, aluminum curtain walls with thermal breaks can achieve U-values as low as 0.8 W/m²K, meeting stringent energy codes. Secondly, aluminum is highly recyclable; it can be reused indefinitely without loss of quality. The recycling process saves up to 95% of the energy required for primary production, drastically cutting greenhouse gas emissions. Many manufacturers now use recycled content in their aluminum products, with some systems containing over 70% post-consumer recycled material. This circular economy approach minimizes waste and conserves natural resources. Additionally, aluminum facades can be designed to support renewable energy integration. For example, building-integrated photovoltaics (BIPV) can be incorporated into aluminum panels, turning the facade into a power-generating surface. Similarly, aluminum systems can accommodate green walls or roofs, promoting biodiversity and improving air quality. Life cycle assessments (LCA) of aluminum facades often show a positive environmental profile, with lower embodied carbon compared to alternatives like steel or concrete when considering full life cycle impacts. Certifications such as LEED or BREEAM reward the use of aluminum for its recyclability and energy performance, further driving adoption in sustainable construction. Moreover, innovations like smart facades—using sensors and automated controls—can optimize energy use by adjusting shading or ventilation based on real-time conditions. Overall, aluminum facades not only reduce operational energy costs but also contribute to a greener built environment, aligning with global sustainability goals such as the UN's Sustainable Development Goals (SDGs).

Практические применения и case studies: успешные проекты с алюминиевыми фасадами

Реальные примеры демонстрируют, как алюминиевые фасады реализуются в variety of projects worldwide, showcasing their versatility and effectiveness. One notable case is the Shard in London, UK, where aluminum was used extensively in the cladding system to create a reflective, shimmering exterior that changes appearance with weather conditions. The facade incorporates high-performance glass and aluminum panels, providing excellent thermal insulation and reducing energy consumption. Another example is the Taipei 101 in Taiwan, which features aluminum curtain walls designed to withstand typhoon-force winds and earthquakes, highlighting the material's structural reliability. In residential construction, aluminum facades are gaining popularity for their modern appeal and low maintenance. For instance, the Bosco Verticale in Milan, Italy, uses aluminum balconies and frames to support its famous vertical forests, combining aesthetics with ecological function. In commercial settings, buildings like the Apple Park in Cupertino, USA, employ custom-anodized aluminum panels to achieve a seamless, minimalist look that reflects the company's design philosophy. These panels are not only durable but also contribute to the building's net-zero energy goals through integrated solar technology. For retrofitting projects, aluminum facades offer a cost-effective way to upgrade older buildings. A case in point is the renovation of the Empire State Building in New York, where aluminum-based systems were installed to improve energy efficiency and modernize the appearance without compromising historical integrity. In public infrastructure, airports and stations often use aluminum facades for their durability and ease of maintenance. For example, the Kempegowda International Airport in Bangalore, India, features large-span aluminum roofs and cladding that provide weather protection and a contemporary aesthetic. Each of these projects underscores the adaptability of aluminum to different climates, budgets, and design requirements. Lessons learned include the importance of proper detailing to prevent water infiltration, the need for quality control in coating applications to ensure longevity, and the value of collaborating with experienced manufacturers to achieve custom solutions. These successes inspire future innovations and demonstrate that aluminum facades are a smart investment for any building type.

Вызовы и решения: overcoming limitations of aluminum facades

Несмотря на многочисленные преимущества, алюминиевые фасады сталкиваются с определенными вызовами, которые require thoughtful solutions. One common issue is thermal expansion and contraction; aluminum has a relatively high coefficient of thermal expansion (about 23 μm/m·°C), which can cause dimensional changes with temperature fluctuations. If not properly accounted for in design, this can lead to stress, distortion, or failure of joints and fasteners. To mitigate this, engineers use expansion joints, sliding connections, and flexible sealants that allow for movement without compromising integrity. Another challenge is acoustic performance; bare aluminum can transmit sound easily, potentially leading to noise issues in buildings. However, this is addressed by using composite panels with acoustic cores or adding insulation layers that dampen sound transmission. For instance, aluminum panels with mineral wool cores can achieve sound reduction indexes (Rw) of over 40 dB, making them suitable for noisy urban environments. Corrosion, while generally low due to the oxide layer, can occur in highly aggressive conditions, such as coastal areas with salt spray or industrial zones with pollutants. Solutions include selecting appropriate alloys (e.g., 5000 or 6000 series for better corrosion resistance), applying protective coatings like anodizing or powder coating, and ensuring regular maintenance to remove contaminants. Fire safety is another concern, as aluminum melts at around 660°C, which could be a risk in fire scenarios. However, aluminum composite panels with fire-resistant cores (e.g., mineral-filled) are designed to meet strict fire ratings, such as Class A or B according to international standards. Additionally, installations should adhere to building codes that mandate fire barriers and sprinkler systems. Cost can be a barrier for some projects, as high-quality aluminum systems may have higher upfront costs compared to alternatives like vinyl or fiber cement. Yet, the long-term benefits—such as durability, low maintenance, and energy savings—often justify the investment. Life cycle cost analyses typically show that aluminum facades have a lower total cost of ownership over decades. Finally, aesthetic uniformity can be challenging due to variations in lighting and viewing angles, but advanced manufacturing techniques ensure consistent color and finish. By addressing these challenges through innovative design, material selection, and adherence to best practices, aluminum facades continue to prove their worth in modern construction.

Будущие тренды и инновации в алюминиевых фасадах

Будущее алюминиевых фасадов looks promising, with emerging trends and innovations set to enhance their performance and appeal. One key trend is the integration of smart technologies; facades are becoming dynamic systems that respond to environmental conditions. For example, electrochromic aluminum panels can change tint to control solar heat gain, improving energy efficiency automatically. Similarly, embedded sensors and IoT devices can monitor structural health, temperature, and air quality, providing data for optimized building management. Another innovation is the development of bio-based coatings and finishes that reduce environmental impact further. Researchers are exploring coatings derived from natural sources, such as plant-based polymers, which offer durability without toxic chemicals. In terms of design, digital fabrication and 3D printing are enabling more complex and customized aluminum components, allowing for unique architectural expressions that were previously impossible. Additive manufacturing can produce lightweight, intricate structures with minimal waste, aligning with sustainability goals. Additionally, the push towards net-zero energy buildings is driving the adoption of energy-generating facades. Aluminum surfaces are being combined with thin-film solar cells or thermoelectric generators to harvest energy from the sun or temperature differences. For instance, transparent aluminum panels with integrated PV cells can generate electricity while maintaining visibility. Material science advancements are also leading to stronger and lighter aluminum alloys, such as those with nano-additives, which enhance mechanical properties without increasing weight. These alloys could enable even larger spans and more daring designs. Furthermore, circular economy principles are becoming standard, with manufacturers designing for disassembly and recycling. Future facades may be modular, allowing easy replacement and upgrading of components, thus extending building lifecycles. In urban planning, aluminum facades are expected to play a role in smart cities, contributing to overall energy grids through vehicle-to-building (V2B) integration or acting as surfaces for urban farming. As climate resilience becomes critical, aluminum facades will likely incorporate adaptive features like water collection systems or shading devices that adjust to extreme weather events. Overall, these innovations will make aluminum facades not only more efficient and sustainable but also integral to the intelligent, responsive buildings of tomorrow.

Заключение: why aluminum surfaces are the future of modern facades

В заключение, алюминиевые поверхности представляют собой идеальное решение для современных фасадов, объединяя в себе прочность, эстетику, энергоэффективность и экологичность. Their historical evolution from niche use to mainstream adoption underscores their reliability and adaptability. The advantages—light weight, corrosion resistance, design flexibility, and recyclability—make them a superior choice over many alternatives. Technological advancements in production and treatment ensure high performance and durability, while practical applications across diverse projects demonstrate their versatility. Challenges such as thermal expansion and fire safety are effectively addressed through engineering innovations, ensuring safety and longevity. Looking ahead, emerging trends like smart facades and sustainable materials will further elevate the role of aluminum in architecture. As cities grow and environmental concerns intensify, aluminum facades offer a path to creating buildings that are not only beautiful and functional but also responsible and future-proof. By choosing aluminum, developers, architects, and owners invest in a material that supports sustainable development, reduces operational costs, and enhances urban landscapes. Whether for new construction or retrofitting, aluminum surfaces are poised to lead the way in the evolution of modern facades, embodying the perfect blend of innovation and tradition.