Широкополосный алюминиевый лист высшего качества

В современной промышленности алюминиевые листы играют ключевую роль благодаря своим исключительным свойствам, таким как легкость, прочность, коррозионная стойкость и экологичность. Среди них широкополосный алюминиевый лист высшего качества выделяется как незаменимый материал для множества применений, от строительства и транспорта до электроники и упаковки. В этой статье мы глубоко погрузимся в мир высококачественных алюминиевых листов, раскрывая их секреты, преимущества и то, как выбрать идеальный продукт для ваших нужд. Если вы инженер, архитектор, производитель или просто энтузиаст, это руководство предоставит вам всю необходимую информацию, чтобы сделать осознанный выбор и максимизировать эффективность ваших проектов.

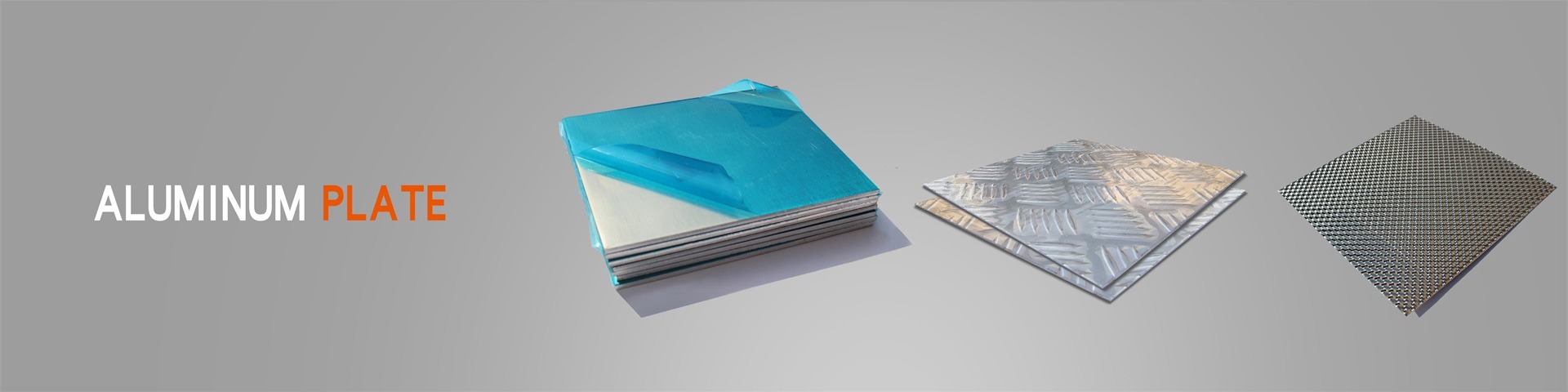

Что такое широкополосный алюминиевый лист?

Широкополосный алюминиевый лист — это плоский прокат из алюминия или его сплавов, производимый в больших ширинах, обычно превышающих 600 мм, с использованием передовых технологий прокатки. Высшее качество означает, что лист соответствует строгим стандартам по чистоте состава, механическим свойствам, однородности толщины и поверхности. Такой лист часто изготавливается из высококачественных алюминиевых сплавов серий 1xxx, 3xxx, 5xxx или 6xxx, которые предлагают оптимальное сочетание прочности, пластичности и устойчивости к коррозии. Процесс производства включает плавку, литье, горячую и холодную прокатку, термическую обработку и отделку, что гарантирует превосходные характеристики для demanding applications.

Ключевые характеристики широкополосного алюминиевого листа высшего качества

Высококачественный алюминиевый лист обладает рядом уникальных свойств, которые делают его предпочтительным выбором в различных отраслях. Во-первых, его малый вес — примерно одна треть веса стали — позволяет снизить общую массу конструкций, что критично для аэрокосмической и automotive industries, где каждый килограмм на счету. Во-вторых, отличная коррозионная стойкость, обеспечиваемая естественным оксидным слоем или дополнительными покрытиями, продлевает срок службы изделий даже в агрессивных средах, таких как морская вода или химические производства. В-третьих, высокая прочность и ударная вязкость, достигаемые за счет легирования и термообработки, позволяют листу выдерживать значительные нагрузки без деформации. Кроме того, хорошая теплопроводность и электропроводность делают его идеальным для теплообменников и электронных компонентов. Наконец, экологичность алюминия, включая 100% recyclability, aligns with modern sustainability goals, reducing environmental impact and supporting circular economy initiatives.

Преимущества использования широкополосного алюминиевого листа

Использование широкополосного алюминиевого листа высшего качества приносит множество benefits across different sectors. In construction, it enables the creation of lightweight yet durable facades, roofs, and structural elements that resist weathering and reduce energy costs due to reflective properties. In transportation, such as automotive and aerospace, it contributes to fuel efficiency by lowering vehicle weight, thereby decreasing emissions and operating costs. In packaging, aluminum sheets provide excellent barrier properties against light, oxygen, and moisture, ensuring product freshness and safety. Moreover, the aesthetic appeal of anodized or painted aluminum surfaces enhances design flexibility, allowing for innovative and visually appealing products. Economically, the long service life and low maintenance requirements result in lower total cost of ownership compared to alternatives like steel or plastics. From a manufacturing perspective, the ease of fabrication—through cutting, bending, welding, and machining—speeds up production processes and reduces waste, boosting overall efficiency and profitability.

Области применения широкополосного алюминиевого листа

Широкополосный алюминиевый лист находит применение в vast array of industries due to its versatile properties. In the construction industry, it is used for cladding, roofing, curtain walls, and structural components in buildings and infrastructure projects, offering durability and modern aesthetics. In the automotive sector, it is employed for body panels, chassis parts, and heat exchangers, helping to meet stringent emissions standards through weight reduction. The aerospace industry relies on high-strength aluminum alloys for aircraft skins, wings, and interior components, where safety and performance are paramount. In electronics, aluminum sheets serve as heat sinks, enclosures, and conductive elements in devices like smartphones and computers. The packaging industry utilizes thin aluminum sheets for cans, foil, and containers, ensuring product protection and shelf life. Additionally, renewable energy sectors, such as solar and wind power, use aluminum for frames and mounting systems due to its corrosion resistance and lightness. Even in everyday consumer goods, from kitchen appliances to furniture, aluminum sheets provide functionality and style. This widespread adoption underscores the material's adaptability and value in modern technology and生活.

Как выбрать широкополосный алюминиевый лист высшего качества

Выбор правильного алюминиевого листа требует careful consideration of several factors to ensure it meets your specific needs. First, determine the alloy type based on application requirements: for example, alloy 1050 or 1100 for high purity and formability in packaging, alloy 3003 for general-purpose use with good corrosion resistance, or alloy 5052 and 6061 for higher strength in structural applications. Second, consider the temper or heat treatment condition, such as O (annealed) for softness and formability, H temper for work-hardened strength, or T temper for precipitation-hardened properties. Third, evaluate the thickness and width: wider sheets reduce seams and improve aesthetics in large panels, while thickness affects strength and weight. Fourth, assess surface finish options, including mill finish, brushed, anodized, or coated surfaces, which influence appearance, durability, and corrosion resistance. Fifth, verify quality certifications from standards like ISO, ASTM, or EN, ensuring the material meets industry benchmarks for composition and performance. Sixth, consider the supplier's reputation, production capabilities, and after-sales support to guarantee reliable supply and technical assistance. Finally, factor in cost-effectiveness by comparing prices per unit weight or area, but prioritize quality to avoid issues like premature failure or increased maintenance. Consulting with experts or requesting samples can help make an informed decision tailored to your project.

Процесс производства широкополосного алюминиевого листа

Производство высококачественного широкополосного алюминиевого листа involves a sophisticated multi-step process that ensures consistency and excellence. It begins with the extraction of bauxite ore, which is refined into alumina through the Bayer process. The alumina is then smelted using the Hall-Héroult process to produce primary aluminum, which is often alloyed with elements like magnesium, silicon, or copper to enhance properties. This molten aluminum is cast into large ingots or slabs using direct chill casting, which minimizes impurities and ensures homogeneity. The slabs are then heated and passed through hot rolling mills to reduce thickness and achieve the desired width, followed by cold rolling for finer control over thickness and surface quality. During rolling, the material may undergo intermediate annealing to relieve stresses and improve ductility. After rolling, the sheets are subjected to various heat treatments, such as solution heat treatment and aging, to develop specific mechanical properties. Surface treatments, including cleaning, etching, and anodizing, are applied to enhance corrosion resistance and appearance. Finally, the sheets are cut to size, inspected for defects using non-destructive testing methods, and packaged for shipment. Advanced technologies like automated control systems and precision instrumentation ensure that each batch meets tight tolerances and quality standards, making modern aluminum production a benchmark of industrial efficiency.

Инновации и будущие тенденции в алюминиевой промышленности

Алюминиевая промышленность continuously evolves with innovations aimed at improving performance, sustainability, and cost-efficiency. One key trend is the development of advanced alloys with enhanced properties, such as higher strength-to-weight ratios or improved fatigue resistance, often through nanotechnology or novel processing techniques. Another innovation is the adoption of digitalization and Industry 4.0 practices, where IoT sensors, AI, and big data analytics optimize production processes, reduce waste, and predict maintenance needs. Sustainability is a major driver, with efforts to increase the use of recycled aluminum, which requires only 5% of the energy needed for primary production, thereby lowering carbon footprint. Additionally, new coating technologies, like nanocoatings or self-healing surfaces, are being explored to extend service life and reduce environmental impact. In terms of applications, the growth of electric vehicles and renewable energy is fueling demand for lightweight aluminum components, while smart packaging with integrated sensors is emerging. Looking ahead, research into bio-based alloys or closed-loop recycling systems promises to make aluminum even more eco-friendly. These advancements ensure that wide aluminum sheets will remain at the forefront of materials science, supporting global challenges like climate change and resource scarcity.

Практические советы по обработке и монтажу алюминиевых листов

Для максимальной эффективности при работе с широкополосными алюминиевыми листами, следуйте practical tips for handling and installation. First, always use appropriate personal protective equipment (PPE), such as gloves and eye protection, to prevent injuries from sharp edges or flying debris. When cutting, employ tools like shears, saws, or laser cutters designed for aluminum to avoid burrs and ensure clean edges; waterjet cutting is excellent for complex shapes without heat-affected zones. For bending, use press brakes with dies that match the alloy's temper to prevent cracking, and consider springback compensation in designs. Welding aluminum requires specific techniques, such as TIG or MIG welding with argon shielding gas, and proper pre-cleaning to remove oxides for strong joints. During installation, ensure that supporting structures are compatible with aluminum's thermal expansion coefficients to avoid stress buildup. Use corrosion-resistant fasteners, like stainless steel or aluminum alloys, to prevent galvanic corrosion. For surface protection, apply sealants or coatings as needed, and avoid contact with dissimilar metals without insulation. Storage should be in dry, covered areas to prevent moisture-induced corrosion, and sheets should be handled carefully to avoid scratches or dents. By adhering to these best practices, you can extend the life of your aluminum products and achieve optimal performance in any application.

Экономические и экологические аспекты алюминиевых листов

Широкополосный алюминиевый лист offers significant economic and environmental benefits that justify its widespread use. Economically, although initial material costs may be higher than some alternatives like steel, the long-term savings from reduced weight, lower energy consumption in transportation, and minimal maintenance often result in a lower total cost of ownership. For instance, in the automotive industry, weight reduction from aluminum can improve fuel efficiency by up to 10%, leading to substantial savings over the vehicle's lifespan. In construction, the durability and recyclability of aluminum reduce replacement and disposal costs. Environmentally, aluminum is a superstar: it is 100% recyclable without loss of quality, and recycling saves up to 95% of the energy required for primary production. This contributes to lower greenhouse gas emissions and conserves natural resources. The production process has also become cleaner with advancements in technology, such as using renewable energy in smelters. Moreover, aluminum's reflectivity can reduce urban heat island effects in cities, and its use in renewable energy systems supports the transition to a low-carbon economy. By choosing high-quality aluminum sheets, businesses and consumers not only benefit from superior performance but also contribute to sustainable development goals, making it a smart choice for the future.

Заключение: Почему широкополосный алюминиевый лист высшего качества — ваш лучший выбор

В заключение, широкополосный алюминиевый лист высшего качества представляет собой unparalleled material that combines lightness, strength, durability, and sustainability in a way that few other materials can match. Whether you are involved in construction, manufacturing, or innovation, its versatility and performance make it an ideal solution for a wide range of applications. By understanding its properties, benefits, and selection criteria, you can harness its full potential to enhance your projects, reduce costs, and support environmental stewardship. As technology advances and global demands shift towards efficiency and sustainability, aluminum will continue to play a critical role in shaping our world. Invest in high-quality aluminum sheets today, and experience the difference that excellence in materials can make. For more information or to explore our product range, contact our experts – we are here to help you succeed.