пять ребер H14 прочность и долговечность в каждом элементе

В современном мире, где инженерные и строительные стандарты постоянно ужесточаются, поиск материалов и конструкций, обеспечивающих максимальную прочность и долговечность, становится ключевым приоритетом. Технология пяти ребер H14 представляет собой революционный прорыв в этой области, предлагая беспрецедентные характеристики, которые делают ее незаменимой для широкого спектра применений. В этой статье мы глубоко исследуем, что такое пять ребер H14, как они работают, их преимущества, применения, и почему они являются будущим надежных конструкций.

Введение в технологию пяти ребер H14

Пять ребер H14 – это инновационная конструктивная особенность, разработанная для усиления структурных элементов, таких как балки, колонны или профили, используемые в строительстве и машиностроении. Термин "H14" относится к специфическому классу прочности материала, часто ассоциируемому с высокопрочными сталями или композитами, которые обладают повышенными механическими свойствами. Добавление пяти ребер – это геометрическое усовершенствование, которое распределяет нагрузки более эффективно, снижает напряжения и повышает общую устойчивость к деформациям и износу.

Исторически, инженеры всегда стремились оптимизировать формы конструкций для достижения лучших показателей. От древних арок и куполов до современных небоскребов, эволюция строительных технологий демонстрирует постоянный поиск баланса между весом, прочностью и cost-effectiveness. Пять ребер H14 emerged as a result of advanced computational modeling and material science, allowing for precise control over stress distribution. Это не просто случайное добавление элементов; это тщательно продуманная система, где каждое ребро играет критическую роль в обеспечении целостности всей структуры.

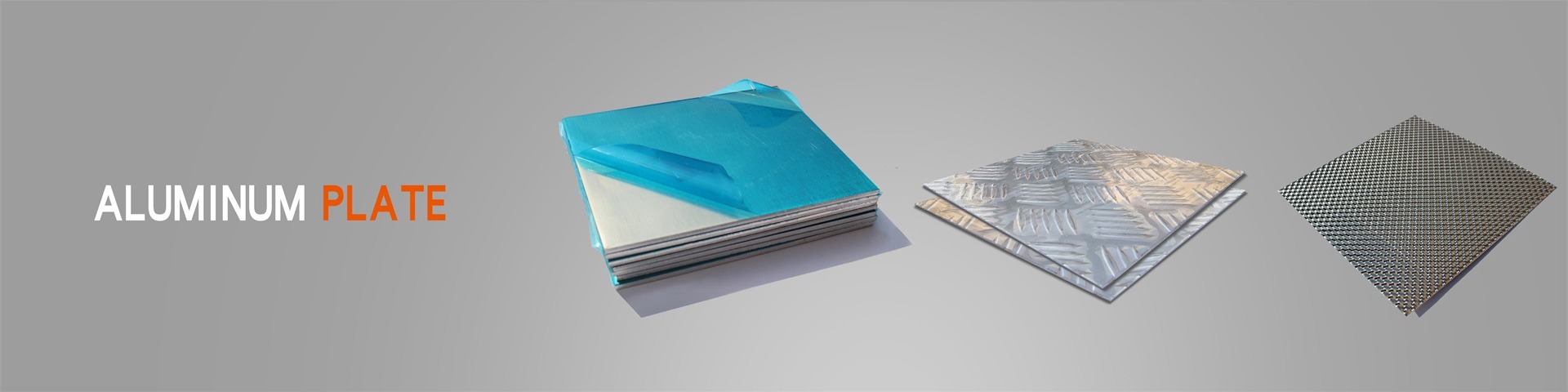

Ключевой аспект этой технологии – ее универсальность. Она может быть применена к различным материалам, включая сталь, алюминий, композиты и даже новые наноматериалы, что делает ее адаптируемой к разнообразным отраслям. Whether in aerospace, automotive, or civil engineering, the principles behind five ribs H14 ensure that every component is built to last, minimizing maintenance costs and enhancing safety.

Научные основы прочности и долговечности

Чтобы fully appreciate the innovation of five ribs H14, it is essential to understand the underlying scientific principles. Прочность материала refers to its ability to withstand applied forces without failure, often measured through parameters like yield strength, tensile strength, and hardness. Долговечность, on the other hand, encompasses resistance to environmental factors such as corrosion, fatigue, and wear over time. The H14 designation typically indicates a material with superior properties in these areas, often achieved through alloying, heat treatment, or advanced manufacturing processes.

The incorporation of five ribs is a geometric optimization that leverages principles from solid mechanics and finite element analysis (FEA). By adding ribs, the moment of inertia of the cross-section is increased, which enhances bending stiffness and reduces deflection under load. This is particularly important in dynamic environments where vibrations and cyclic loading can lead to fatigue failure. The ribs act as stiffeners, distributing stresses away from critical points and preventing the initiation of cracks.

Moreover, the number five is not arbitrary; it is chosen based on simulations that show optimal stress distribution for common loading scenarios. Too few ribs might not provide sufficient reinforcement, while too many could add unnecessary weight and complexity. Five ribs strike a balance, offering maximal strength with minimal material usage, aligning with sustainable design practices. This approach reduces the ecological footprint by minimizing waste and energy consumption during production and throughout the lifecycle of the product.

Additionally, the H14 material often includes coatings or surface treatments to enhance durability. For example, galvanization or powder coating can protect against corrosion, while shot peening can improve fatigue resistance. When combined with the ribbed design, these features create a synergy that significantly extends the service life of components, sometimes doubling or tripling it compared to conventional designs.

Преимущества технологии пяти ребер H14

Одним из наиболее compelling advantages of the five ribs H14 technology is its exceptional strength-to-weight ratio. By optimizing the geometry, engineers can achieve higher load-bearing capacities without increasing the overall weight of the structure. This is crucial in applications where weight savings translate to improved efficiency, such as in automotive or aerospace industries. For instance, in vehicle design, lighter components lead to better fuel economy and reduced emissions, contributing to environmental sustainability.

Another significant benefit is enhanced durability. The ribbed design mitigates common failure modes like buckling, cracking, and deformation. In harsh environments, such as coastal areas with high salinity or industrial settings with aggressive chemicals, the H14 material's resistance to corrosion ensures long-term reliability. This reduces the frequency of repairs and replacements, lowering lifecycle costs and minimizing downtime in critical operations.

The technology also offers improved safety. In structural engineering, the ability to predict and control stress concentrations means that buildings and bridges can withstand extreme events like earthquakes or high winds more effectively. The five ribs help dissipate energy during impacts, reducing the risk of catastrophic failure. This is why regulatory bodies increasingly recommend or mandate such innovations in safety-critical applications.

Furthermore, the aesthetic aspect should not be overlooked. Modern design often requires that functional elements also contribute to visual appeal. The ribbed pattern can be incorporated into architectural designs to create visually striking facades or interiors, blending form and function seamlessly. This versatility makes it appealing not only to engineers but also to architects and designers seeking innovative solutions.

From an economic perspective, although the initial cost of implementing five ribs H14 might be higher due to advanced manufacturing techniques, the long-term savings are substantial. Reduced maintenance, longer lifespan, and improved performance lead to a lower total cost of ownership. Additionally, as the technology becomes more widespread, economies of scale are driving down production costs, making it accessible to a broader range of projects.

Применения в различных отраслях

Технология пяти ребер H14 finds applications across numerous industries, each benefiting from its unique properties. In construction, it is used in beams, columns, and frameworks for buildings, bridges, and infrastructure projects. For example, in skyscrapers, the ribbed design allows for taller structures with thinner profiles, saving space and materials while ensuring stability against lateral forces like wind.

In the automotive sector, components such as chassis frames, suspension systems, and body panels incorporate five ribs H14 to enhance crashworthiness and reduce weight. This contributes to better vehicle performance and safety ratings. Electric vehicles, in particular, benefit from weight reduction to extend battery range, making this technology a key enabler of the transition to sustainable mobility.

The aerospace industry relies on high-strength, lightweight materials for aircraft fuselages, wings, and engine parts. Five ribs H14 components help achieve the rigorous standards required for airworthiness, reducing fuel consumption and increasing payload capacity. Similarly, in marine engineering, ships and offshore structures use these elements to resist corrosion from seawater and withstand dynamic loads from waves.

Beyond these, the technology is applied in consumer goods, such as furniture and appliances, where durability and design are important. Even in sports equipment, like bicycles or protective gear, the ribbed design enhances performance and safety. The adaptability of five ribs H14 ensures that it can be tailored to specific needs, whether for high-performance racing cars or everyday household items.

Looking forward, emerging fields like renewable energy are adopting this technology. Wind turbine blades and solar panel supports benefit from the enhanced strength and durability, ensuring reliable operation in challenging environments. As the world moves towards a more sustainable future, innovations like five ribs H14 will play a pivotal role in enabling resilient and efficient infrastructure.

Будущие тенденции и инновации

The future of five ribs H14 technology is bright, with ongoing research focused on further optimization and integration with digital tools. Advances in additive manufacturing, or 3D printing, allow for the creation of complex ribbed structures that were previously impossible to produce with traditional methods. This enables customizations for specific applications, reducing material waste and lead times.

Artificial intelligence and machine learning are being used to refine the design process. By analyzing vast datasets from simulations and real-world performance, AI algorithms can suggest optimal rib configurations for new materials or loading conditions. This accelerates innovation and ensures that each iteration of the technology is more efficient than the last.

Sustainability will continue to be a driving force. Researchers are exploring bio-based materials and recyclable composites that can be used with the five ribs design, reducing environmental impact. Lifecycle assessment tools are being integrated to evaluate the total ecological footprint, from production to disposal, encouraging circular economy practices.

Moreover, as global challenges like climate change and urbanization intensify, the demand for robust infrastructure will grow. Five ribs H14 technology is poised to meet these demands, offering solutions that are not only strong and durable but also smart. For instance, embedded sensors in ribbed structures can monitor health in real-time, enabling predictive maintenance and enhancing safety through IoT connectivity.

In conclusion, the five ribs H14 technology represents a significant leap forward in engineering. Its combination of strength, durability, and versatility makes it a cornerstone of modern design across industries. As we continue to push the boundaries of what is possible, this innovation will undoubtedly play a crucial role in building a safer, more efficient, and sustainable world.

Заключение

В summary, технология пяти ребер H14 воплощает в себе лучшие достижения материаловедения и инженерного дизайна. Обеспечивая unparalleled прочность и долговечность, она revolutionizes how we approach construction and manufacturing. От небоскребов до автомобилей, ее применения демонстрируют универсальность и эффективность. По мере развития технологий, мы можем ожидать еще более инновационных адаптаций, которые продолжат улучшать нашу жизнь. Investing in such advancements is not just about building better products; it is about creating a resilient future for generations to come.

For anyone involved in design, engineering, or procurement, understanding and adopting five ribs H14 technology is essential. It offers a competitive edge, enhances safety, and contributes to sustainability goals. As the industry evolves, staying ahead of the curve with such innovations will be key to success. Let's embrace this technology and build a world where every element is strong, durable, and reliable.