5754H111 алюминиевая плита премиум качество для прочных конструкций

В современном мире строительства и инженерии выбор материалов играет ключевую роль в обеспечении долговечности, безопасности и эффективности конструкций. Среди множества вариантов алюминиевые сплавы выделяются своими уникальными свойствами, и 5754H111 алюминиевая плита премиум качества представляет собой один из наиболее надежных и востребованных продуктов на рынке. В этой статье мы подробно рассмотрим, почему эта плита стала синонимом прочности и инноваций, обсудим её технические характеристики, области применения, сравнительные преимущества, а также будущие тенденции в использовании. Мы углубимся в детали, чтобы предоставить исчерпывающее руководство для профессионалов и энтузиастов, стремящихся к оптимальным решениям в строительстве и производстве.

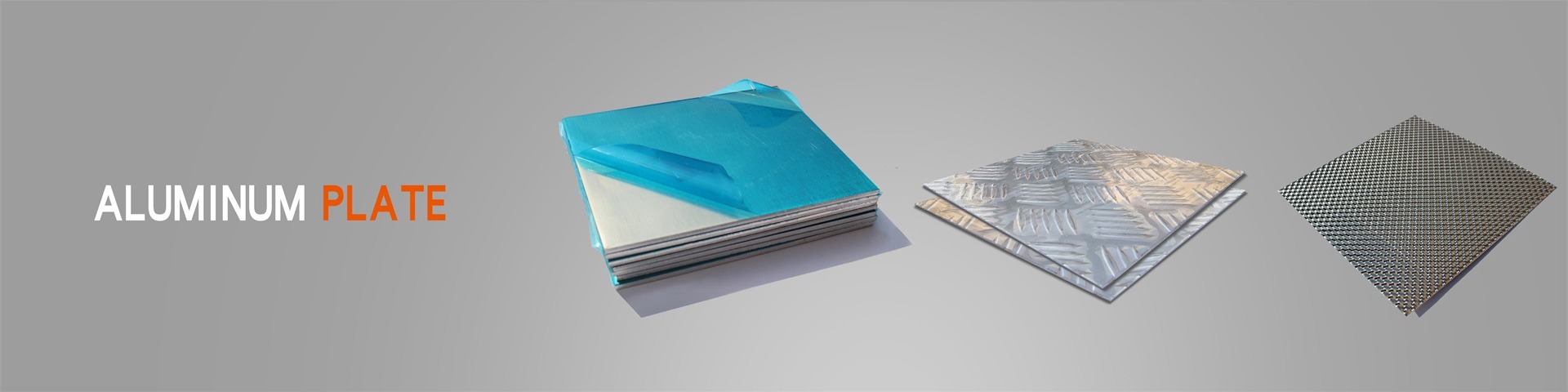

Введение в алюминиевые сплавы и их значение

Алюминий, как металл, известен своей легкостью, коррозионной стойкостью и отличной теплопроводностью. Однако в чистом виде он не всегда подходит для высоконагруженных применений из-за относительно низкой прочности. Именно здесь на сцену выходят алюминиевые сплавы, которые сочетают алюминий с другими элементами, такими как магний, марганец или кремний, чтобы enhance его механические свойства. Сплавы серии 5xxx, к которой относится 5754H111, особенно популярны благодаря высокому содержанию магния, что придает им превосходную прочность, свариваемость и устойчивость к коррозии, особенно в морских и агрессивных средах.

Исторически, развитие алюминиевых сплавов началось в начале 20 века, и с тех пор они эволюционировали to meet the growing demands of industries like aerospace, automotive, and construction. The 5754 alloy, in particular, has been standardized internationally, with the H111 temper indicating a specific heat treatment that optimizes its properties for forming and structural applications. This makes it an ideal choice for projects where weight reduction, durability, and cost-effectiveness are paramount.

In today's context, with increasing emphasis on sustainability and energy efficiency, aluminum alloys offer a green alternative to heavier materials like steel, as they are recyclable and require less energy for production. The 5754H111 плита embodies these benefits, making it a cornerstone in modern engineering practices. As we delve deeper, we will explore how this material stands out and why it should be the go-to option for robust constructions.

Технические характеристики 5754H111 алюминиевой плиты

To fully appreciate the capabilities of the 5754H111 aluminum plate, it is essential to understand its technical specifications. This alloy is primarily composed of aluminum with magnesium as the main alloying element, typically ranging from 2.6% to 3.6%, along with small amounts of manganese, chromium, and other elements to enhance specific properties. The H111 temper refers to a process where the material is strain-hardened and then partially annealed, resulting in a good balance of strength and formability.

Key mechanical properties include a tensile strength of approximately 180-240 MPa, yield strength of 80-150 MPa, and elongation at break of around 12-16%, depending on thickness and processing. These values make it suitable for applications requiring moderate to high strength without sacrificing ductility. Additionally, its density is about 2.7 g/cm³, which is significantly lower than steel, contributing to weight savings in structures.

The corrosion resistance of 5754H111 is exceptional, thanks to the formation of a protective oxide layer. It performs well in various environments, including fresh water, seawater, and industrial atmospheres, making it ideal for marine applications, chemical processing equipment, and outdoor structures. Its weldability is another standout feature; it can be easily welded using common techniques like MIG or TIG welding without significant loss of properties, which is crucial for fabricating complex assemblies.

Thermal and electrical conductivity are also notable; while not as high as pure aluminum, they are sufficient for many applications, such as heat exchangers or electrical enclosures. The plate is available in various thicknesses, from thin sheets to thick plates, allowing for versatility in design. Standards such as ISO, ASTM, and EN govern its production, ensuring consistency and quality across batches. This reliability is why industries trust 5754H111 for critical components.

Области применения: Где сияет 5754H111

The versatility of the 5754H111 aluminum plate translates into a wide range of applications across multiple sectors. In the construction industry, it is commonly used for structural frameworks, roofing, cladding, and facades due to its strength-to-weight ratio and corrosion resistance. For instance, in high-rise buildings or bridges, using this material can reduce overall weight, lower foundation costs, and enhance seismic performance. Its aesthetic appeal, with options for anodizing or painting, also makes it popular in architectural designs.

In transportation, particularly in automotive and aerospace, 5754H111 is employed for body panels, chassis components, and interior parts. The weight savings contribute to improved fuel efficiency and reduced emissions, aligning with global sustainability goals. In marine applications, such as boat hulls, decks, and superstructures, its resistance to saltwater corrosion ensures longevity and safety, even in harsh conditions.

Industrial uses include machinery frames, pressure vessels, and storage tanks, where its weldability and durability are critical. In the energy sector, it is used in solar panel frames and wind turbine components, leveraging its light weight and environmental resistance. Even in everyday consumer products, like furniture or electronic housings, 5754H111 finds a place due to its malleability and modern look.

Case studies highlight its success; for example, a recent project in shipbuilding utilized 5754H111 plates for the hull of a cargo vessel, resulting in a 15% weight reduction and extended service life. Similarly, in construction, a skyscraper in a coastal city used this material for its facade, combating corrosion from salty air while maintaining structural integrity. These examples underscore its practical benefits and why it is a preferred choice for engineers and designers.

Сравнительный анализ: 5754H111 против других материалов

When selecting materials for strong constructions, it is vital to compare options to make informed decisions. Let's pit 5754H111 against common alternatives like steel, other aluminum alloys, and composites.

Compared to carbon steel, 5754H111 offers significant weight savings (about one-third the density), better corrosion resistance, and easier fabrication. However, steel generally has higher strength and lower cost per unit weight, making it better for extremely high-load applications. But for many scenarios, the total cost of ownership, including maintenance and lifecycle, favors aluminum due to its durability and recyclability.

Against other aluminum alloys, such as 6061 or 5083, 5754H111 stands out for its excellent formability and weldability. Alloy 6061 is stronger but less corrosion-resistant and harder to weld, while 5083 is similar but often used for more specialized marine applications. 5754H111 strikes a balance, making it a versatile all-rounder. Composites, like fiber-reinforced polymers, offer high strength and light weight but can be expensive, difficult to repair, and less recyclable.

In terms of environmental impact, aluminum alloys like 5754H111 are highly recyclable, with up to 95% energy savings compared to primary production. This contrasts with materials like plastics or certain metals that have higher carbon footprints. Lifecycle assessments show that using 5754H111 can reduce overall environmental impact in long-term projects, especially in sectors focused on green building certifications.

Cost-wise, while the initial price of aluminum might be higher than some materials, the long-term benefits often justify the investment. Reduced maintenance, longer lifespan, and energy savings in transportation applications make it economically viable. For instance, in automotive use, the fuel savings from weight reduction can offset the material cost over the vehicle's life.

Будущие тенденции и инновации

The future of aluminum alloys, including 5754H111, looks promising with ongoing advancements in material science and manufacturing technologies. Additive manufacturing, or 3D printing, is opening new possibilities for creating complex geometries with aluminum, allowing for customized and optimized designs that were previously impossible. This could lead to even lighter and stronger structures using 5754H111 in innovative ways.

Sustainability is a major driver; as regulations tighten on emissions and waste, the recyclability of aluminum becomes increasingly valuable. Research is focused on improving recycling processes to make them more efficient and cost-effective, potentially lowering the environmental footprint further. Additionally, developments in surface treatments, such as nano-coatings, could enhance the corrosion resistance and durability of 5754H111 plates, expanding their use in even more aggressive environments.

In the context of smart cities and IoT, integrating sensors into aluminum structures could enable real-time monitoring of stress, temperature, and corrosion, leading to predictive maintenance and enhanced safety. 5754H111, with its good mechanical properties, could be a substrate for such technologies, revolutionizing how we manage infrastructure.

Market trends indicate growing demand in emerging economies for construction and transportation, where lightweight and durable materials are essential. As global urbanization continues, products like 5754H111 will play a crucial role in building resilient and efficient cities. Collaborations between industry and academia are likely to yield new alloys or treatments that build on the strengths of 5754H111, ensuring it remains at the forefront of material innovation.

Заключение: Почему выбирать 5754H111

In summary, the 5754H111 aluminum plate premium quality is an exceptional material for strong constructions, offering a blend of strength, lightweight, corrosion resistance, and versatility that is hard to match. Its technical properties make it suitable for a wide array of applications, from construction and transportation to industrial and marine uses. When compared to other materials, it provides a balanced option that prioritizes long-term performance and sustainability.

As we look to the future, innovations in manufacturing and a focus on green solutions will only enhance its appeal. For professionals and decision-makers, investing in 5754H111 means opting for reliability, efficiency, and a step towards a more sustainable world. Whether you're designing a new building, a vehicle, or any robust structure, this aluminum plate should be a top consideration for achieving excellence in engineering and design.

We encourage readers to explore further, consult with experts, and consider real-world case studies to see the benefits firsthand. The journey towards stronger, smarter constructions starts with choosing the right materials, and 5754H111 is undoubtedly a leader in that realm.