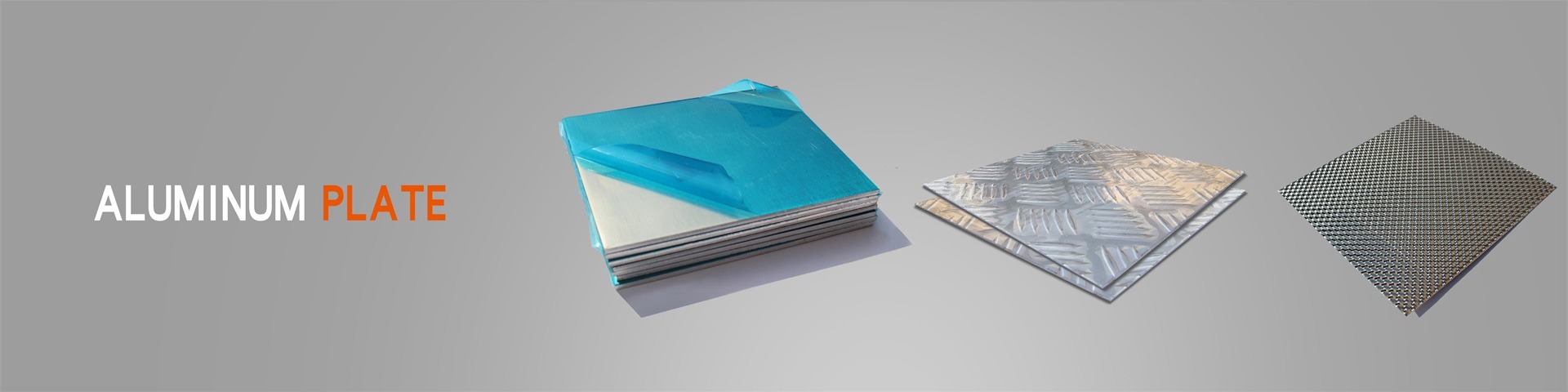

Широкоформатная алюминиевая плита 3003 меняет ваше производство

В современном мире промышленности и технологий поиск материалов, которые сочетают в себе прочность, лёгкость, долговечность и экономическую эффективность, становится ключевым фактором успеха. Среди множества вариантов алюминиевая плита 3003 выделяется как один из наиболее универсальных и инновационных продуктов, способных кардинально изменить подход к производственным процессам. В этой статье мы подробно рассмотрим, почему широкоформатная алюминиевая плита 3003 является game-changer для вашего бизнеса, анализируя её свойства, преимущества, области применения и будущие тенденции. Мы углубимся в технические детали, приведём примеры из реальной практики и предложим стратегии для интеграции этого материала в ваши операции, обеспечивая конкурентное преимущество на глобальном рынке.

Введение в алюминиевую плиту 3003: Основы и исторический контекст

Алюминий, как материал, имеет богатую историю, восходящую к началу 20 века, когда его производство стало массовым благодаря electrolytic процессам. Сплав 3003, в частности, был разработан как модификация pure алюминия, с добавлением марганца (обычно около 1.2%), что значительно улучшает его механические свойства без существенного увеличения веса. Широкоформатные плиты из этого сплава представляют собой листы больших размеров, часто превышающие стандартные габариты, что делает их идеальными для масштабных промышленных применений, где требуется минимальное количество швов и высокая структурная целостность. Эволюция алюминиевых сплавов, таких как 3003, отражает общую тенденцию в материаловедении: стремление к оптимизации performance при снижении environmental impact. В контексте производства, переход на широкоформатные варианты позволяет компаниям streamline their processes, reduce waste, and enhance product quality. Это не просто материал; это стратегический актив, который может redefine how industries operate, from automotive to construction and beyond. В последние десятилетия, с ростом awareness о sustainability, алюминий 3003 gain дополнительную популярность due to its recyclability and energy-efficient production methods, making it a cornerstone of green manufacturing initiatives worldwide.

Ключевые свойства алюминиевой плиты 3003: Почему она исключительна

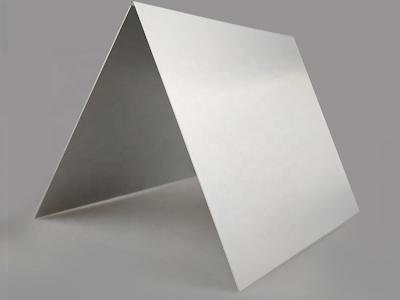

Алюминиевая плита 3003 обладает набором уникальных характеристик, которые делают её предпочтительным выбором для diverse applications. Во-первых, её коррозионная стойкость выдающаяся: благодаря presence марганца, она образует protective oxide layer that resists rust and degradation in various environments, including marine and industrial settings. Это свойство особенно ценно в отраслях, где equipment подвергается воздействию влаги или химикатов, таких как shipbuilding или chemical processing. Во-вторых, mechanical strength: while not as strong as some high-strength alloys like 6061, 3003 offers a excellent balance of strength and ductility, with a tensile strength of about 110-150 MPa, depending on temper. This allows it to be easily formed, bent, or stamped without cracking, which is crucial for manufacturing complex shapes in automotive or aerospace components. Третье, lightweight nature: алюминий примерно в три раза легче steel, что приводит к significant weight savings in end-products, improving fuel efficiency in vehicles or reducing structural load in buildings. Кроме того, thermal and electrical conductivity are high, making it suitable for heat exchangers, radiators, and electronic enclosures. Наконец, обрабатываемость: 3003 легко поддаётся machining, welding, and finishing processes, such as anodizing or painting, which enhances its aesthetic appeal and functionality. Эти свойства collectively contribute to its versatility and cost-effectiveness, as they reduce the need for additional treatments or materials, lowering overall production costs and time. For instance, in the construction industry, широкоформатные плиты 3003 can be used for roofing or cladding, providing durability and modern appearance while minimizing maintenance requirements. In summary, the combination of corrosion resistance, formability, light weight, and conductivity makes aluminum 3003 a superior material that can adapt to evolving industrial demands.

Преимущества использования широкоформатной алюминиевой плиты 3003 в производстве

Интеграция широкоформатной алюминиевой плиты 3003 в производственные процессы приносит multitude benefits that can revolutionize operations. One of the primary advantages is enhanced efficiency: large-format plates reduce the number of joints and seams in assemblies, leading to faster installation times and improved structural integrity. This is particularly beneficial in sectors like aerospace or automotive, where every minute saved in production translates to cost savings and increased output. For example, in aircraft manufacturing, using wide aluminum sheets minimizes the need for riveting or welding, resulting in lighter and more aerodynamic frames. Secondly, cost reduction: although the initial cost of aluminum might be higher than some alternatives, the long-term savings are substantial due to reduced maintenance, longer lifespan, and lower energy consumption during use. Additionally, the recyclability of aluminum means that scrap can be repurposed, further lowering material costs and supporting circular economy principles. Thirdly, sustainability: aluminum production, especially with advanced smelting technologies, has become more energy-efficient over time. The 3003 alloy, being highly recyclable (with up to 95% energy savings compared to primary production), aligns with global environmental goals, such as reducing carbon footprints. Companies adopting this material can enhance their corporate social responsibility profiles and comply with stricter regulations on emissions. Fourthly, design flexibility: the formability of 3003 allows for innovative product designs that were previously impossible with heavier or less ductile materials. In architecture, for instance, wide aluminum plates enable the creation of curved facades or large-span structures without compromising strength. Lastly, improved product performance: end-products made from 3003 often exhibit better resistance to fatigue and impact, leading to higher customer satisfaction and reduced warranty claims. A case study from the automotive industry shows that vehicles incorporating aluminum components experience fewer corrosion-related issues and better fuel economy, directly impacting brand reputation and sales. Overall, the advantages of wide-format aluminum 3003 extend beyond mere material properties to encompass operational, economic, and environmental gains, making it a smart investment for forward-thinking manufacturers.

Области применения: Где алюминиевая плита 3003 находит своё место

Широкоформатная алюминиевая плита 3003 находит применение в wide array of industries, thanks to its adaptable properties. In the construction sector, it is commonly used for roofing, siding, and structural panels in commercial and residential buildings. Its corrosion resistance ensures longevity in harsh weather conditions, while its light weight simplifies transportation and installation. For example, in high-rise constructions, aluminum cladding made from 3003 reduces the overall load on the framework, allowing for taller and more innovative designs. In transportation, this material is pivotal in automotive bodies, train carriages, and marine vessels. The automotive industry benefits from its use in body panels, heat shields, and trim components, where weight reduction is critical for meeting fuel efficiency standards. A notable application is in electric vehicles (EVs), where aluminum helps offset the weight of batteries, extending range and performance. In aerospace, 3003 is used for non-structural parts like interior panels or ductwork due to its ease of fabrication and resistance to fatigue. The electronics industry utilizes it for heat sinks, enclosures, and chassis in devices like computers and smartphones, leveraging its thermal conductivity to dissipate heat effectively. Additionally, in packaging, although less common for wide-format plates, aluminum 3003 is used in cans and containers, but the focus here is on industrial-scale sheets. Other niches include signage, where its durability and finish options make it ideal for outdoor advertising, and in renewable energy projects, such as solar panel frames, where corrosion resistance is essential for long-term exposure. The versatility of 3003 means that it can be tailored to specific needs through alloy modifications or treatments, expanding its applicability even further. As industries continue to evolve towards lightweighting and sustainability, the demand for wide-format aluminum 3003 is expected to grow, driven by innovations in manufacturing techniques like additive manufacturing or advanced joining methods. This broad applicability underscores its role as a transformative material that can be integrated into virtually any production chain to enhance performance and efficiency.

Сравнение с другими материалами: Почему алюминий 3003 превосходит конкурентов

При выборе материалов для производства, важно сравнить алюминиевую плиту 3003 с alternatives such as steel, other aluminum alloys, or composites. Steel, for instance, offers higher strength but is significantly heavier, leading to increased transportation costs and higher energy consumption in applications like vehicles or buildings. While high-strength steels exist, they often lack the corrosion resistance of aluminum, requiring protective coatings that add complexity and cost. In contrast, aluminum 3003 provides a better strength-to-weight ratio, making it more efficient for weight-sensitive applications. Compared to other aluminum alloys, such as 6061 or 5052, 3003 strikes a balance: it has better formability than 6061 (which is stronger but less ductile) and better corrosion resistance than 5052 (which is more malleable but less robust in harsh environments). For wide-format applications, 3003's uniformity and ease of welding give it an edge over alloys that might crack or warp during processing. Composites, like carbon fiber, offer extreme lightness and strength but are expensive, difficult to recycle, and can be brittle under impact. Aluminum 3003, being metallic, is more predictable in behavior and easier to repair or modify. Additionally, from a cost perspective, aluminum 3003 is generally more affordable than composites or specialized steels, especially when considering total lifecycle costs including maintenance and disposal. Environmental factors also play a role: aluminum has a higher recyclability rate compared to many composites or coated steels, reducing its ecological footprint. In terms of availability, aluminum is abundant and widely produced, ensuring supply chain stability. Real-world examples highlight these advantages: in the marine industry, aluminum hulls made from 3003 last longer than steel ones due to superior corrosion resistance, reducing downtime and repair costs. Similarly, in consumer electronics, aluminum enclosures provide a premium feel and better heat management than plastic alternatives. Thus, while no material is perfect for every scenario, aluminum 3003 often emerges as the optimal choice for applications requiring a combination of lightness, durability, and cost-effectiveness, outperforming competitors in many key metrics.

Технологии обработки и manufacturing: Как работать с широкоформатной плитой

Эффективная обработка широкоформатной алюминиевой плиты 3003 требует specialized techniques to harness its full potential. First, cutting: large-format plates can be cut using methods like laser cutting, waterjet cutting, or plasma cutting, each offering precision and minimal material waste. Laser cutting is particularly popular for its accuracy and speed, ideal for intricate designs in industries like automotive or electronics. Second, forming: due to its excellent ductility, 3003 can be easily bent, rolled, or stamped into desired shapes without cracking. Hydraulic presses or roll forming machines are commonly used, and processes like deep drawing are feasible for creating complex parts. Third, joining: welding is a key aspect, with techniques such as MIG (Metal Inert Gas) or TIG (Tungsten Inert Gas) welding being suitable for 3003. Proper filler materials and parameters must be used to avoid issues like porosity or weakening of the heat-affected zone. Alternatively, mechanical fastening or adhesive bonding can be employed for applications where welding is not desirable. Fourth, finishing: anodizing is a common treatment for aluminum 3003, enhancing its corrosion resistance and allowing for colorful finishes. Painting or powder coating can also be applied for aesthetic or protective purposes. Fifth, quality control: non-destructive testing methods, such as ultrasonic testing or eddy current testing, ensure that the plates meet specifications for thickness, flatness, and integrity. In manufacturing, automation plays a big role: CNC machines and robotics can handle large-format plates efficiently, reducing human error and increasing throughput. For instance, in the production of aircraft components, automated systems precisely cut and form aluminum sheets to tight tolerances. Additionally, advances in additive manufacturing are beginning to incorporate aluminum powders, though for wide-format plates, traditional subtractive methods remain dominant. It's crucial to consider the temper of the aluminum (e.g., O-temper for annealed softness or H32 for strain-hardened) based on the application, as it affects machinability and strength. Best practices include storing plates in dry conditions to prevent oxidation before processing and using appropriate lubricants during machining to extend tool life. By mastering these technologies, manufacturers can maximize the benefits of aluminum 3003, leading to higher productivity and better end-products. Training workforce on these techniques is also essential to avoid defects and ensure safety, as handling large metal sheets requires proper equipment and protocols.

Экономические и экологические аспекты: Cost-benefit анализ

Внедрение широкоформатной алюминиевой плиты 3003 involves a thorough cost-benefit analysis that highlights its economic and environmental merits. Economically, the initial investment in aluminum might be higher than for materials like steel or plastic, but the long-term savings are compelling. For example, in the construction industry, using aluminum for cladding reduces maintenance costs due to its corrosion resistance, leading to lower lifecycle expenses. Transportation costs are also reduced because of its light weight, saving fuel and logistics expenses. In production, the efficiency gains from wide-format plates—such as fewer assembly steps and less waste—translate to lower labor costs and higher output rates. A study by industry analysts shows that companies switching to aluminum 3003 can achieve a return on investment within 2-3 years through these savings. Additionally, the recyclability of aluminum means that scrap value is high, and companies can participate in buy-back programs, further offsetting costs. From an environmental perspective, aluminum production has evolved to become more sustainable. Modern smelters use renewable energy sources and advanced technologies to reduce greenhouse gas emissions. The recycling process for aluminum requires only 5% of the energy needed for primary production, making it a key player in circular economy models. By using recycled aluminum 3003, manufacturers can significantly lower their carbon footprint and comply with regulations like the EU's Green Deal or carbon taxes. Moreover, the durability of aluminum products means less frequent replacement, reducing resource consumption and waste generation. Lifecycle assessments (LCA) demonstrate that aluminum-based products often have a lower environmental impact compared to alternatives when considering entire product life, from extraction to disposal. For instance, in the automotive sector, aluminum-intensive vehicles emit fewer CO2 emissions over their lifetime due to better fuel efficiency. However, challenges remain, such as the energy-intensive nature of primary aluminum production, but ongoing innovations in electrolysis and energy sourcing are mitigating these issues. Overall, the economic benefits of reduced operational costs and the environmental advantages of sustainability make aluminum 3003 a wise choice for businesses aiming to balance profitability with planetary health. Companies should conduct their own analyses based on specific applications to quantify these benefits accurately.

Будущие тенденции и инновации: Что ждёт алюминиевую промышленность

Алюминиевая промышленность, и specifically the use of wide-format 3003 plates, is poised for significant evolution driven by technological advancements and market demands. One major trend is the increase in automation and Industry 4.0 integration: smart factories will use IoT sensors and AI to optimize the production and handling of aluminum sheets, ensuring perfect quality and minimal waste. For example, real-time monitoring during rolling or cutting processes can detect defects early, reducing scrap rates. Another innovation is in material science: researchers are developing enhanced versions of 3003 with nano-additives or composite layers to improve strength, conductivity, or other properties without compromising weight. Additive manufacturing (3D printing) with aluminum powders is also expanding, though for large-format applications, it may complement rather than replace traditional methods. In terms of sustainability, the push for green aluminum—produced using renewable energy—is gaining momentum, with certifications like ASI (Aluminum Stewardship Initiative) becoming more common. This will make aluminum 3003 even more attractive to eco-conscious consumers and regulators. Additionally, the rise of electric vehicles and renewable energy infrastructure will drive demand for lightweight, durable materials, positioning 3003 as a key enabler. In construction, trends towards prefabrication and modular building will benefit from wide-format plates that allow for faster assembly and design flexibility. Geopolitically, supply chain resilience is a focus, with efforts to localize production and reduce dependence on imports, which could lead to more regional manufacturing hubs for aluminum products. Furthermore, digital twins and simulation software will allow manufacturers to test and optimize designs virtually before physical production, saving time and resources. Looking ahead, we might see the integration of aluminum with smart technologies, such as embedded sensors for structural health monitoring in buildings or vehicles. These innovations will not only enhance the performance of aluminum 3003 but also open up new applications in emerging fields like space exploration or advanced robotics. For businesses, staying abreast of these trends is crucial to leverage the full potential of this material and maintain a competitive edge. Investing in R&D and partnerships with technology providers can help capitalize on these future opportunities, ensuring that aluminum 3003 continues to transform production landscapes for years to come.

Практические рекомендации для внедрения: Как начать использовать алюминиевую плиту 3003

Для компаний, рассматривающих переход на широкоформатную алюминиевую плиту 3003, several practical steps can facilitate a smooth integration. First, conduct a comprehensive assessment of current production processes to identify where aluminum 3003 can replace existing materials. Engage with engineers and designers to evaluate potential applications and calculate the expected benefits in terms of cost, weight savings, and performance. Second, source reliable suppliers: choose manufacturers with certifications for quality (e.g., ISO standards) and experience in producing wide-format plates. Request samples and perform tests to ensure the material meets your specific requirements for thickness, temper, and surface finish. Third, invest in training for your workforce: ensure that operators are skilled in handling, cutting, forming, and joining aluminum. This might involve workshops or collaborations with technical institutes. Fourth, upgrade equipment if necessary: large-format plates may require specialized machinery like wide-bed CNCs or large presses. Consider leasing or phased investments to manage costs. Fifth, implement a recycling program: set up systems to collect and recycle aluminum scrap, which can generate additional revenue and support sustainability goals. Sixth, pilot test the material in a small-scale project before full-scale adoption to iron out any issues and demonstrate value to stakeholders. For example, use aluminum 3003 for a prototype product or a section of a larger assembly to gauge its performance. Seventh, monitor key performance indicators (KPIs) such as production time, defect rates, and energy consumption to measure the impact of the change. Eighth, stay informed about industry trends and innovations through conferences, publications, or partnerships with research organizations. Finally, communicate the benefits to customers and marketing teams to enhance brand image and drive sales. By following these recommendations, companies can minimize risks and maximize the advantages of aluminum 3003, leading to a successful transformation of their production capabilities. Remember, the goal is not just to adopt a new material but to embrace a holistic approach that aligns with long-term strategic objectives.

Заключение: Преобразуйте своё производство с алюминиевой плитой 3003

В заключение, широкоформатная алюминиевая плита 3003 представляет собой мощный инструмент для модернизации и оптимизации производственных процессов across various industries. Её уникальные свойства—коррозионная стойкость, лёгкость, обрабатываемость и экологичность—делают её идеальным выбором для companies striving to improve efficiency, reduce costs, and meet sustainability targets. From construction to transportation, the applications are vast and growing, driven by technological advancements and changing market demands. By adopting this material, businesses can not only enhance their product offerings but also position themselves as leaders in innovation and environmental stewardship. The future holds even greater potential with ongoing research and trends towards automation and green manufacturing. However, successful implementation requires careful planning, investment in skills and equipment, and a commitment to continuous improvement. We encourage you to explore the possibilities with aluminum 3003 and take the first step towards transforming your production landscape. Embrace this change, and witness how a simple material upgrade can lead to profound improvements in performance, profitability, and planetary health. The era of intelligent manufacturing is here, and aluminum 3003 is at its forefront—ready to change your production for the better.

Эта статья предоставила всесторонний обзор широкоформатной алюминиевой плиты 3003, но remember, что каждый production environment уникален. Консультируйтесь с experts и проводите tailored analyses чтобы ensure optimal results. Спасибо за внимание, и удачи в ваших инновационных endeavors!