H18 пятиреберная алюминиевая плита превосходный выбор для строительных проектов

В современном строительстве выбор материалов играет ключевую роль в обеспечении долговечности, безопасности и экономической эффективности проектов. Среди множества вариантов H18 пятиреберная алюминиевая плита выделяется как инновационное решение, которое объединяет в себе высокую прочность, легкость и устойчивость к коррозии. Эта статья подробно обсуждает, почему данная плита является превосходным выбором для строительных проектов, подкрепляя аргументы техническими данными, сравнительным анализом и реальными примерами применения. Мы рассмотрим ее свойства, преимущества перед традиционными материалами, влияние на экологию и экономику, а также перспективы использования в будущем.

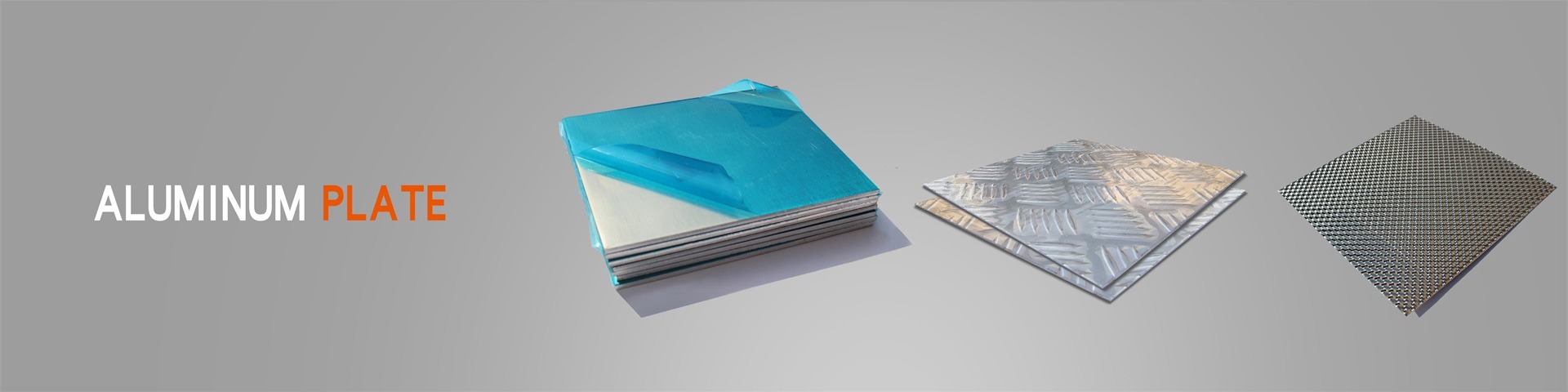

1. Введение в H18 пятиреберную алюминиевую плиту

H18 пятиреберная алюминиевая плита представляет собой специализированный строительный материал, изготовленный из алюминиевого сплава марки H18, который характеризуется высокой прочностью и твердостью благодаря процессу холодной обработки. Пятиреберная конструкция добавляет структурную жесткость, распределяя нагрузки более эффективно и повышая устойчивость к изгибу и деформации. Алюминий как материал известен своей легкостью — его плотность составляет около 2,7 г/см³, что примерно в три раза меньше, чем у стали, что делает его идеальным для снижения веса конструкций без ущерба для прочности. Кроме того, алюминий обладает естественной устойчивостью к коррозии благодаря образованию защитного оксидного слоя, что продлевает срок службы материала в агрессивных средах, таких как влажный климат или промышленные зоны.

Исторически алюминий начал широко использоваться в строительстве с середины XX века, особенно в качестве облицовочных материалов и каркасов. Однако с развитием технологий, таких как экструзия и прокатка, алюминиевые сплавы стали более разнообразными и оптимизированными для конкретных применений. Сплав H18, например, относится к серии сплавов 6000 или 7000 (в зависимости от конкретного состава), которые часто содержат добавки магния и кремния для улучшения механических свойств. Пятиреберный профиль — это инженерное усовершенствование, которое увеличивает момент инерции плиты, позволяя ей выдерживать более высокие нагрузки при меньшем весе. Это делает H18 пятиреберную алюминиевую плиту particularly подходящей для applications, где важны both strength and weight reduction, such as in high-rise buildings, bridges, and modular constructions.

В контексте современного строительства, где все больше внимания уделяется sustainability and efficiency, алюминиевые материалы like the H18 ribbed plate offer significant advantages. Они не only reduce the overall weight of structures, leading to savings in foundation and support costs, but also contribute to energy efficiency during transportation and installation. Moreover, aluminum is highly recyclable, with recycling rates exceeding 90% in many regions, which aligns with green building standards such as LEED or BREEAM. This introduction sets the stage for a deeper exploration of why the H18 пятиреберная алюминиевая плита is not just a material choice but a strategic investment for future-proof construction projects.

2. Технические характеристики и свойства

H18 пятиреберная алюминиевая плита обладает рядом выдающихся технических характеристик, которые делают ее привлекательной для строительства. Во-первых, механические свойства: прочность на растяжение typically ranges from 300 to 400 MPa for H18 tempered aluminum, depending on the specific alloy composition. This is comparable to many structural steels but with a much lower density, resulting in a higher strength-to-weight ratio. The five-rib design enhances stiffness, with a moment of inertia that can be up to 50% higher than that of a flat plate of the same weight, according to engineering simulations. This means that the plate can span longer distances without additional support, reducing the need for beams or columns and simplifying design.

Коррозионная стойкость is another critical property. Aluminum naturally forms a thin, adherent oxide layer that protects it from further oxidation. In the H18 temper, this resistance is further enhanced through alloying elements like magnesium and silicon, which improve durability in humid, saline, or acidic environments. For instance, tests show that H18 aluminum plates can withstand exposure to salt spray for over 1000 hours without significant degradation, whereas steel might require protective coatings that add cost and maintenance. Additionally, the material is non-combustible and has a high melting point (around 660°C), contributing to fire safety in buildings.

Теплопроводность and electrical conductivity of aluminum are also beneficial in construction. High thermal conductivity (about 200 W/m·K) allows for efficient heat dissipation, which can be advantageous in applications like facades or roofing to reduce cooling loads. However, this might require insulation in some cases to prevent thermal bridging. The lightweight nature — a typical H18 пятиреберная плита weighs approximately 5-10 kg/m², compared to 20-40 kg/m² for steel plates — facilitates easier handling, transportation, and installation, reducing labor costs and time. Dimensional stability is excellent, with low thermal expansion coefficients (around 23×10^{-6}/°C), minimizing issues with expansion and contraction in varying temperatures.

These properties are backed by international standards such as ISO or ASTM, ensuring consistency and reliability. For example, the H18 temper is defined by specific hardness and strength criteria, often verified through hardness testing (e.g., Brinell hardness of 95-100 HB). In practice, this means that builders can rely on predictable performance, whether in seismic zones where flexibility is needed or in high-wind areas where rigidity is crucial. The combination of these technical attributes makes the H18 пятиреберная алюминиевая плита a versatile and high-performance material for a wide range of structural and non-structural applications.

3. Преимущества перед традиционными материалами

По сравнению с традиционными строительными материалами, такими как сталь, бетон или дерево, H18 пятиреберная алюминиевая плита предлагает ряд существенных преимуществ. One of the most significant is weight reduction. As mentioned, aluminum's low density allows for lighter structures, which can lead to cost savings in foundations, supports, and transportation. For instance, in a high-rise building, reducing the weight by 30% using aluminum components can decrease the load on the foundation, potentially allowing for simpler and cheaper designs. This is particularly important in areas with poor soil conditions or where seismic activity is a concern, as lighter structures tend to perform better in earthquakes due to lower inertial forces.

Коррозионная стойкость sets aluminum apart from steel, which often requires galvanization or painting to prevent rust. These protective measures add initial costs and ongoing maintenance — for example, steel structures might need repainting every 5-10 years, whereas aluminum can last decades without such interventions. In marine environments or industrial settings, this advantage is even more pronounced, as aluminum resists salt and chemical corrosion effectively. Additionally, aluminum does not suffer from issues like rot or insect damage, which are common with wood, making it a more durable choice in the long term.

Экологичность is another key benefit. Aluminum is highly recyclable, and the recycling process requires only about 5% of the energy needed to produce primary aluminum from bauxite ore. This not only reduces the carbon footprint but also supports circular economy principles. In contrast, concrete production is a major source of CO2 emissions due to cement manufacturing, and steel recycling, while common, still involves significant energy input. By choosing H18 пятиреберная алюминиевая плита, builders can contribute to greener construction practices and potentially earn credits in sustainability certifications.

Эстетика и гибкость design are also advantages. Aluminum can be easily extruded or formed into complex shapes, allowing for innovative architectural designs. The five-rib pattern itself can add visual interest to facades or ceilings, and the material can be anodized or painted in various colors without compromising its properties. In terms of installation, the lightweight nature means faster assembly times, which can accelerate project timelines and reduce labor costs. For example, in modular construction, aluminum panels can be prefabricated off-site and quickly installed on-site, minimizing disruption and improving efficiency.

However, it's important to note potential drawbacks. Aluminum generally has a higher initial cost compared to steel or concrete, but this is often offset by lower lifecycle costs due to reduced maintenance and longer service life. Additionally, in applications where very high strength is required, such as in heavy load-bearing elements, steel might still be preferable. But for many modern construction needs, the H18 пятиреберная алюминиевая плита represents a balanced and superior choice.

4. Применение в различных строительных проектах

H18 пятиреберная алюминиевая плита finds applications across a diverse range of construction projects, thanks to its versatile properties. In высотное строительство, it is commonly used for curtain walls, façades, and structural panels. The lightweight nature reduces the overall building load, allowing for taller structures without excessive foundation requirements. For instance, in skyscrapers like the Burj Khalifa, aluminum components were extensively used to achieve weight savings and aesthetic appeal. The five-rib design adds rigidity, making it suitable for wind-resistant cladding that can withstand high pressures without deformation.

In мостостроение, aluminum plates are employed for decking and support elements. The corrosion resistance is crucial here, especially for bridges exposed to de-icing salts or marine environments. A notable example is the Millau Viaduct in France, where aluminum was used in parts to reduce weight and enhance durability. The H18 пятиреберная плита can serve as a lightweight alternative to concrete or steel decks, reducing dead load and allowing for longer spans or simpler support structures. This not only cuts construction costs but also extends the bridge's lifespan with minimal maintenance.

Промышленное строительство benefits from the material's durability and ease of installation. In warehouses, factories, or storage facilities, aluminum plates can be used for roofing, siding, or flooring. The high reflectivity of aluminum can help in reducing heat gain, contributing to energy efficiency in climate control. Additionally, in modular or prefabricated construction, the five-rib pattern allows for quick assembly and disassembly, making it ideal for temporary structures or buildings that require flexibility, such as exhibition halls or emergency shelters.

Гражданское строительство, including residential and commercial buildings, also sees widespread use. For roofing systems, the lightweight aluminum plates reduce the load on walls and foundations, potentially lowering construction costs. In interiors, they can be used for ceilings, partitions, or decorative elements, offering a modern and sleek appearance. The material's non-combustibility enhances fire safety, which is a critical consideration in building codes. Real-world case studies, such as the use in sustainable housing projects in Scandinavia, demonstrate how aluminum plates contribute to energy-efficient and durable homes.

Moreover, in specialized applications like aerospace hangars or sports facilities, the high strength-to-weight ratio of H18 пятиреберная алюминиевая плита allows for large, open spaces without obstructive supports. For example, in stadium roofs, the material can cover vast areas while resisting weather elements. The versatility extends to renovation projects, where existing structures can be upgraded with aluminum components to improve performance and aesthetics without major overhauls. Overall, the applicability of this material is broad, driven by its adaptability to various design requirements and environmental conditions.

5. Экономические аспекты и окупаемость инвестиций

Экономический анализ использования H18 пятиреберной алюминиевой плиты в строительных проектах reveals both initial costs and long-term savings that justify its adoption. Initially, the material cost per unit area is higher compared to conventional options like steel or concrete. For instance, aluminum might cost 2-3 times more than equivalent steel plates, primarily due to the energy-intensive production process. However, this upfront investment is often counterbalanced by reductions in other areas. The lightweight nature leads to savings in transportation — shipping costs are lower because fewer trips are needed, and handling requires less heavy machinery, reducing fuel consumption and labor expenses.

During construction, the ease of installation accelerates project timelines. Studies show that using prefabricated aluminum components can cut construction time by up to 20%, which directly translates to lower labor costs and earlier project completion, allowing for sooner occupancy or rental income. For example, in a commercial building project, saving weeks on the schedule can mean significant financial benefits. Additionally, the reduced weight minimizes the need for robust foundations and supports, which can account for 10-15% of total construction costs in traditional buildings. This structural efficiency allows for more economical design without compromising safety.

Long-term, the durability and low maintenance requirements of aluminum result in substantial lifecycle cost savings. Unlike steel, which may need regular painting or coating to prevent corrosion, aluminum's innate resistance means maintenance intervals are extended or eliminated. Over a 50-year lifespan, the total cost of ownership for an aluminum structure can be 30-40% lower than for a steel equivalent, when factoring in maintenance, repairs, and potential replacements. Insurance costs might also be lower due to improved fire resistance and structural integrity.

Return on investment (ROI) can be enhanced through energy efficiency. Aluminum's reflective properties can reduce cooling loads in buildings, leading to lower energy bills. In green building certifications, the use of recyclable materials like aluminum can qualify for incentives or tax breaks, further improving economic viability. For instance, projects aiming for LEED certification might earn points for material selection, potentially increasing property value. Case studies, such as the renovation of office buildings with aluminum facades, have shown payback periods of 5-10 years through energy savings and increased tenant appeal.

However, it's crucial to conduct a detailed cost-benefit analysis for each project, considering local material prices, labor rates, and environmental factors. In regions with high corrosion risks or strict sustainability regulations, the economic advantages of H18 пятиреберная алюминиевая плита are more pronounced. Overall, while the initial outlay is higher, the long-term economic benefits make it a wise investment for forward-thinking construction projects.

6. Экологические соображения и устойчивое развитие

В контексте растущего внимания к устойчивому развитию H18 пятиреберная алюминиевая плита предлагает значительные экологические преимущества. Первичное производство алюминия из бокситовой руды энергоемко и связано с выбросами парниковых газов — на производство одной тонны первичного алюминия требуется около 14,000-16,000 кВт·ч электроэнергии, что может приводить к выбросам CO2 в зависимости от источника энергии. Однако высокий потенциал переработки смягчает это воздействие. Переработанный алюминий требует только 5% энергии от первичного производства, и global recycling rates for aluminum are over 70%, making it one of the most recycled materials worldwide.

Использование H18 пятиреберной плиты в строительстве способствует circular economy by reducing waste. At the end of a building's life, aluminum components can be easily dismantled and recycled without loss of quality, unlike materials like concrete, which often end up in landfills. This aligns with principles of sustainable construction, such as those outlined in frameworks like Cradle to Cradle or the UN Sustainable Development Goals. For example, in deconstruction projects, aluminum can be recovered and reused in new buildings, minimizing resource extraction and environmental degradation.

Энергоэффективность в эксплуатации is another environmental benefit. The lightweight nature of aluminum reduces the energy required for transportation during construction, lowering the carbon footprint associated with logistics. In building operation, aluminum's high reflectivity can contribute to reducing urban heat island effects and decreasing the need for air conditioning, thus saving energy. For instance, cool roofs made from reflective aluminum panels can lower indoor temperatures by several degrees, reducing electricity consumption for cooling by up to 15% in warm climates.

Сравнение с другими материалами highlights aluminum's superiority in terms of lifecycle assessment (LCA). Studies show that over its lifetime, an aluminum structure has a lower total environmental impact than steel or concrete when considering factors like embodied energy, carbon emissions, and water usage. For example, the production of cement for concrete is responsible for approximately 8% of global CO2 emissions, whereas aluminum's impact is more concentrated in the initial phase but mitigated through recycling. By choosing H18 пятиреберная алюминиевая плита, builders can support biodiversity conservation by reducing mining activities for virgin materials.

Moreover, the material's durability means fewer replacements and less frequent maintenance, further reducing its environmental footprint over time. Initiatives such as green building certifications (e.g., BREEAM, LEED) often reward the use of recyclable and durable materials, providing additional incentives for adoption. In summary, while not without environmental costs, the H18 пятиреберная алюминиевая плита represents a step towards more sustainable construction practices, balancing performance with ecological responsibility.

7. Будущие тенденции и инновации

Будущее H18 пятиреберной алюминиевой плиты в строительстве looks promising, driven by ongoing innovations and evolving market trends. One key area is advancements in material science. Researchers are developing new aluminum alloys with enhanced properties, such as higher strength or improved corrosion resistance, through nanoengineering or additive manufacturing. For instance, alloys with scandium or zirconium additions are being explored to achieve strength levels comparable to titanium while maintaining aluminum's lightweight advantages. These innovations could make the H18 пятиреберная плита even more competitive in high-performance applications, like seismic-resistant buildings or aerospace-inspired architectures.

Цифровизация и BIM (Building Information Modeling) are transforming how materials are used in construction. With BIM, designers can simulate the performance of aluminum plates in virtual environments, optimizing designs for weight, cost, and sustainability before physical implementation. This reduces waste and ensures that the five-rib pattern is utilized to its fullest potential. Additionally, IoT (Internet of Things) sensors can be integrated into aluminum structures to monitor health in real-time, providing data on stress, corrosion, or temperature changes, which enables predictive maintenance and enhances safety.

Тенденции в устойчивом строительстве will continue to favor materials like aluminum. As governments worldwide implement stricter carbon reduction targets and green building codes, the demand for recyclable and energy-efficient materials will grow. For example, the European Green Deal aims for climate neutrality by 2050, which will incentivize the use of low-carbon materials in construction. The H18 пятиреберная алюминиевая плита, with its high recyclability and potential for low embodied carbon through recycled content, is well-positioned to meet these regulations.

Применение в умных городах and modular construction is another growth area. In smart cities, lightweight and durable materials are essential for rapid deployment of infrastructure. Aluminum plates can be used in smart grids, renewable energy installations, or adaptive buildings that respond to environmental changes. Modular construction, which is gaining popularity for its efficiency, relies on prefabricated components like the H18 плита for quick assembly. This trend is accelerated by urbanization and the need for affordable housing, where speed and cost-effectiveness are paramount.

However, challenges remain, such as the volatility of aluminum prices due to global market fluctuations or the need for improved recycling infrastructure in some regions. But with continued investment in R&D and collaboration between industry and academia, the H18 пятиреберная алюминиевая плита is likely to see expanded use. Innovations like 3D printing of aluminum components could further customize designs and reduce waste. In conclusion, the future holds exciting possibilities for this material, making it a cornerstone of next-generation construction.

8. Заключение

В заключение, H18 пятиреберная алюминиевая плита emerges as a superior choice for construction projects due to its unique combination of strength, lightness, corrosion resistance, and sustainability. Throughout this article, we have explored its technical properties, advantages over traditional materials, diverse applications, economic benefits, environmental impacts, and future potential. The material not only addresses immediate construction needs but also aligns with long-term goals of efficiency and ecological responsibility.

By adopting H18 пятиреберная алюминиевая плита, builders and developers can achieve projects that are not only structurally sound and aesthetically pleasing but also cost-effective and green. As the construction industry evolves towards more innovative and sustainable practices, this material stands out as a reliable and forward-thinking option. We encourage professionals to consider its integration in their next projects, leveraging its full potential to create buildings that are built to last and kind to the planet.